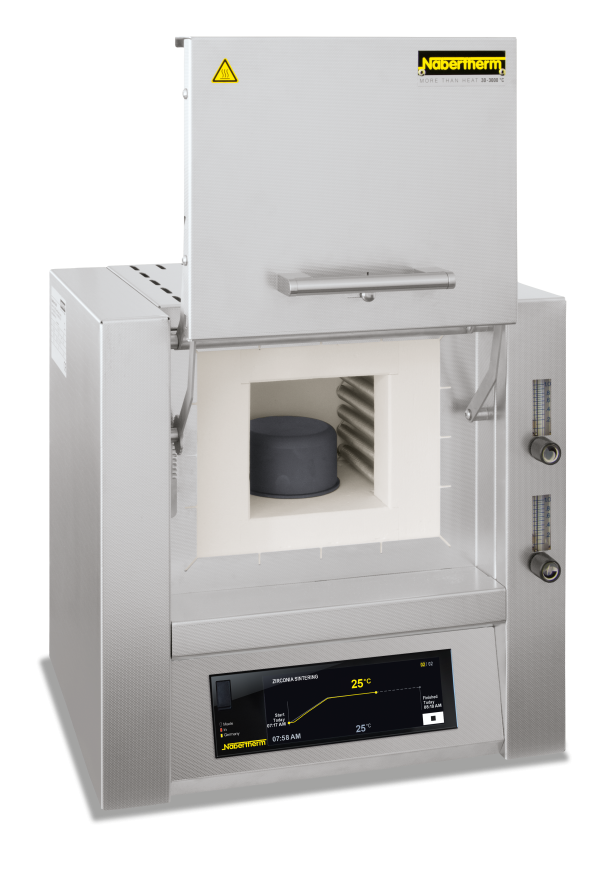

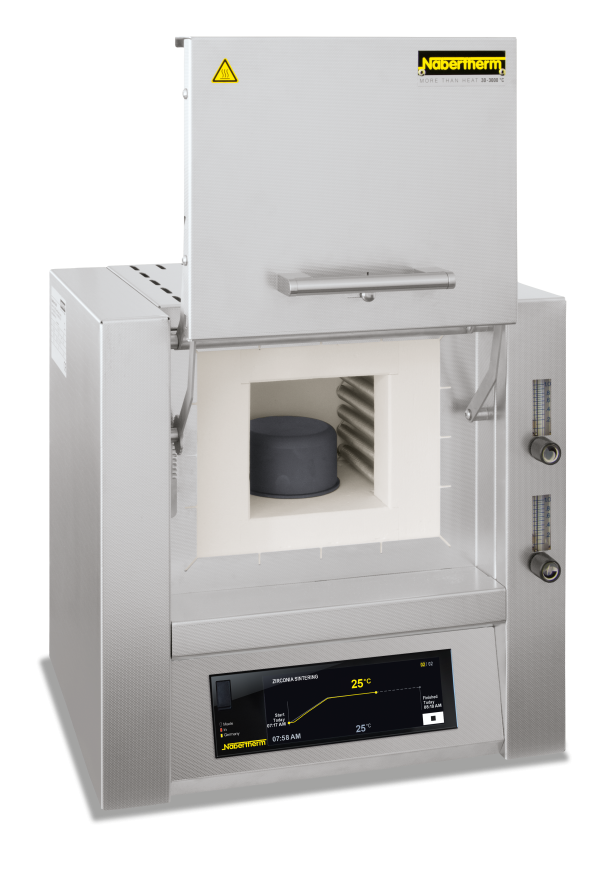

The sintering furnace LT 02/13 CR is perfectly suited for sintering of cobalt-chromium restorations. The blanks are placed in a special sintering bell and will be heat-treated under argon. The specific design in combination with sintering pearls provides for good sintering results in a nearly oxygen-free atmosphere at very low argon consumption. The system is open and can be programmed for various materials up to sintering temperatures of 1300 °C. Two pre-installed sample programs, which can be adjusted individually. Furthermore, the sintering furnace LT 02/13 CR is designed for a single-phase connection.

- Tmax 1300 °C

- Working temperature up to 1280 °C, depending on the CoCr material

- Single-phase connection

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used

- Gas supply system with 2 solenoid valves and 2 flow meter

- Forced cooling system with compressed air possible

- Sintering bell with good sealing for sintering up to 30 single crowns under argon

- Sintering pearls, Ø 1,25 mm (200 g) included in delivery scope

- Special tongs included in the delivery scope

- Type S thermocouple

- Freely programmable controller C550 allows for automatic temperature control and switching of the gas flow

- Switching system with solid-state-relays to switch the heating

- Possibility to set two gas quantities for optimal adjustment to the sintering process

- Controller with touch operation C550 (10 programs with each 20 segments)

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

- Freeware NTEdit for convenient program input via MS Excel on the PC

- Freeware NTGraph for evaluation and documention of firings using MS Excel on the PC

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Defined application within the constraints of the operating instructions