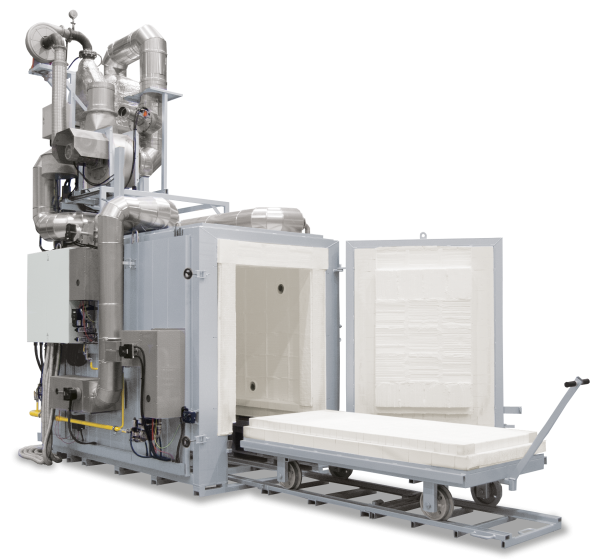

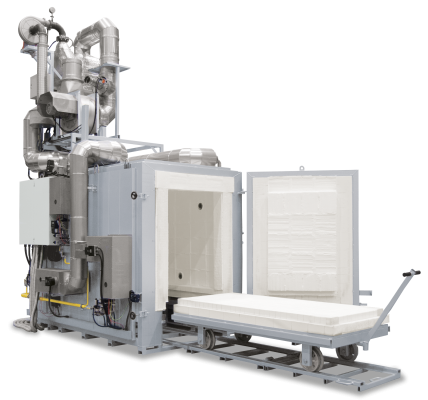

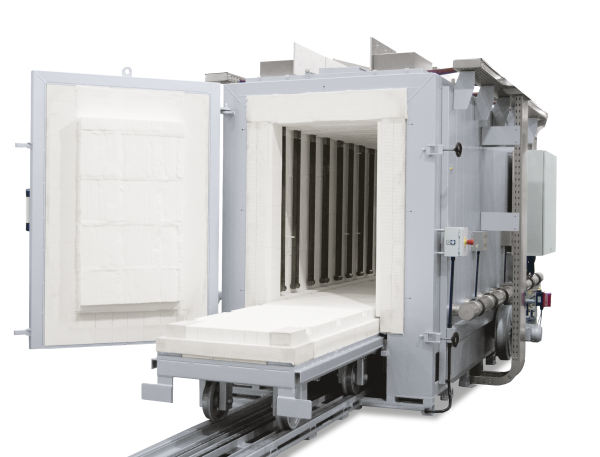

Gas-fired bogie hearth furnaces distinguish by their unique efficiency. The use of high-speed burners allows for short heating times. The burners are arranged according to the furnace geometry providing for a optimum temperature uniformity. Depending on the furnace dimensions, the burners can alternatively be equipped with recuperator technology to save energy. The high-quality, long-life fiber insulation, classified as non-carcinogenic, with storage capacity provides for short heating and cooling times.

- Tmax up to 1400 °C, depending on furnace design

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

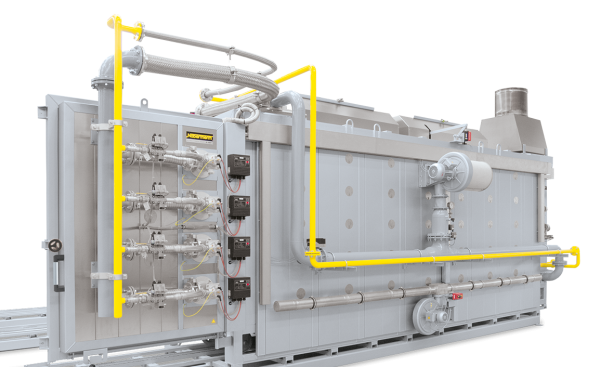

- Powerful, sturdy high-speed burner with special flame control in the furnace chamber provide for optimum temperature uniformity

- Operation with city gas, natural gas or liquified gas

- Fully automatic PLC control of the temperature as well as monitoring of the burner function

Reduction-resistant fiber insulation with low heat storage provides for short heating and cooling times. - Exhaust hood with fittings for further discharge of the exhaust gases

- Defined application within the constraints of the operating instructions