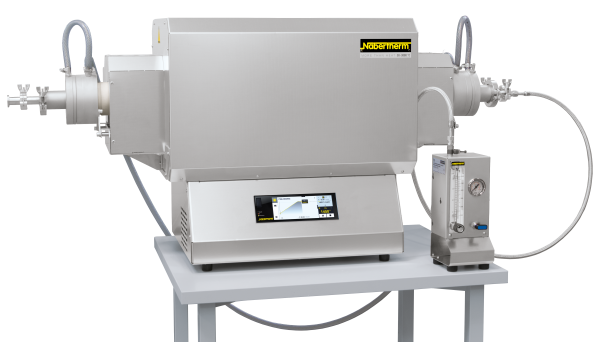

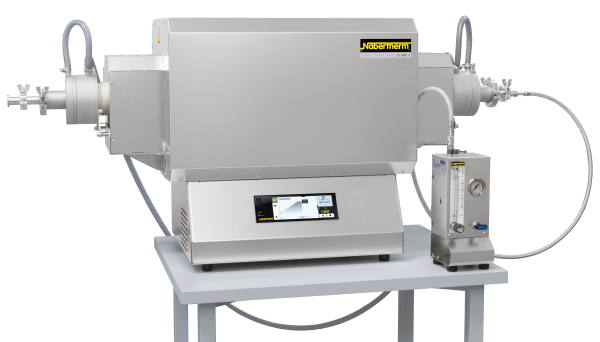

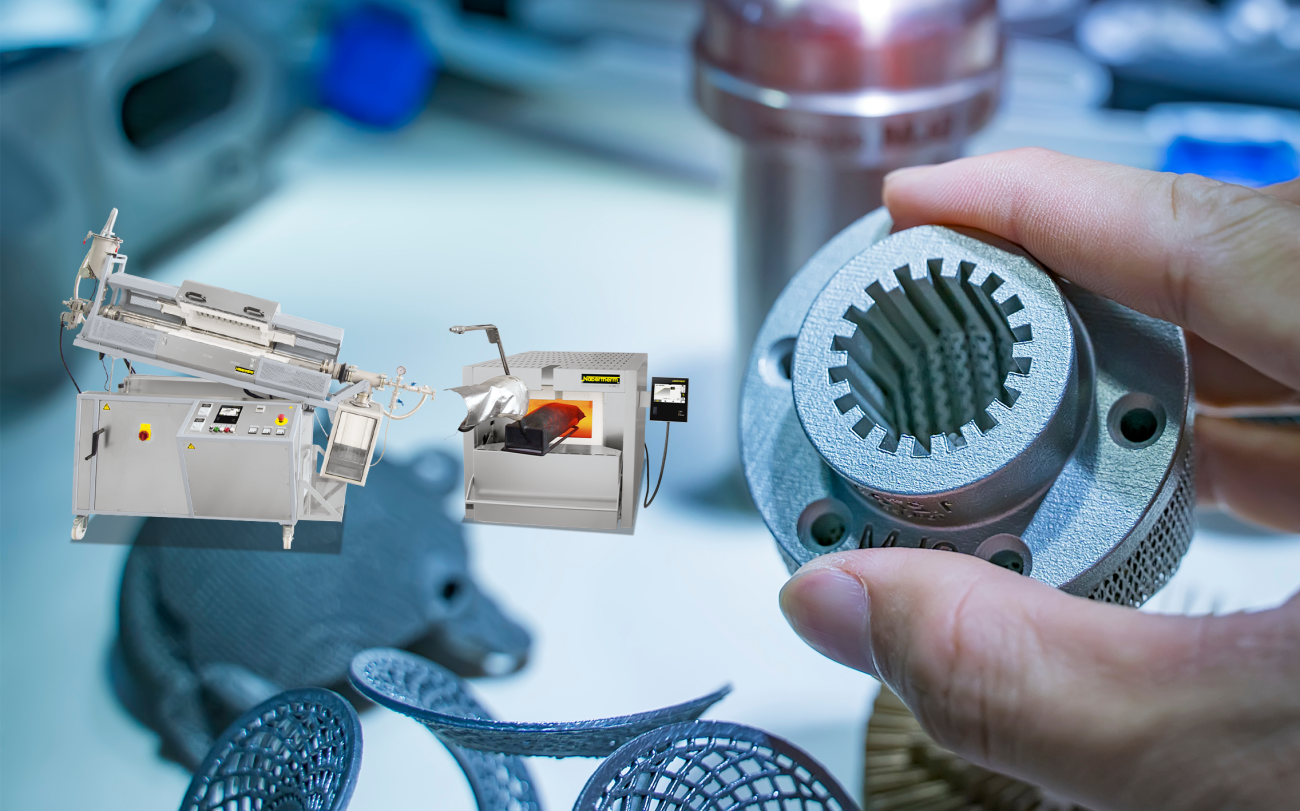

Tube Furnaces with Stand for Horizontal and Vertical Operation up to 1500 °C

Vertical or horizontal operation infinitely adjustable.

Function and equipment

Tube furnace RT 50/250/13

Horizontal operation

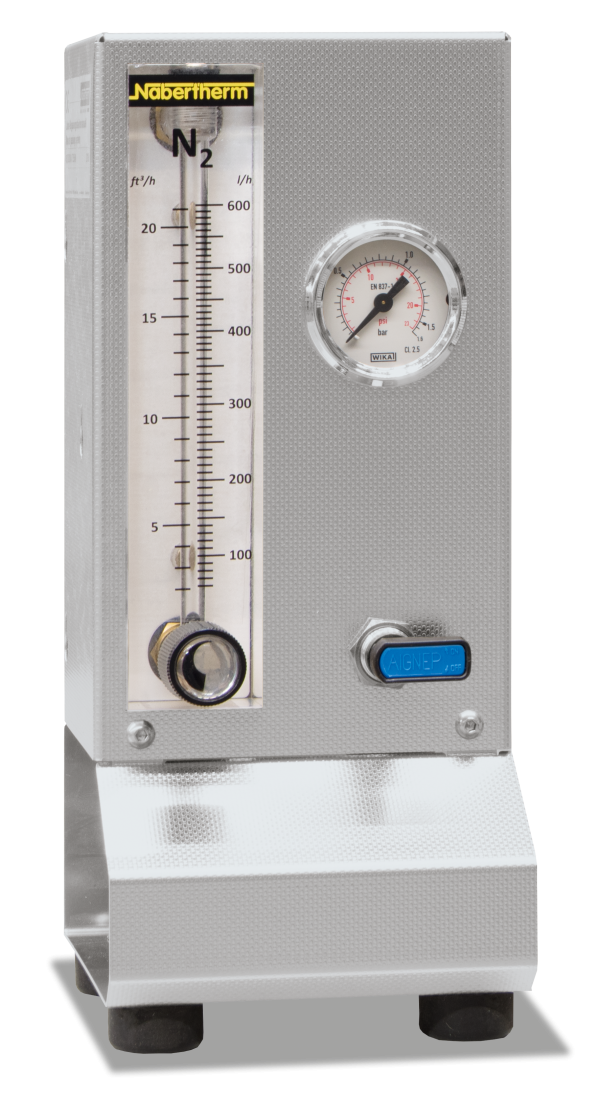

Gas panel for one non-flammable protective or reactive gas (N2, Ar, He, CO2, air, forming gas)

Gas panel for one non-flammable process gas (N2, Ar, He, CO2, air, forming gas)

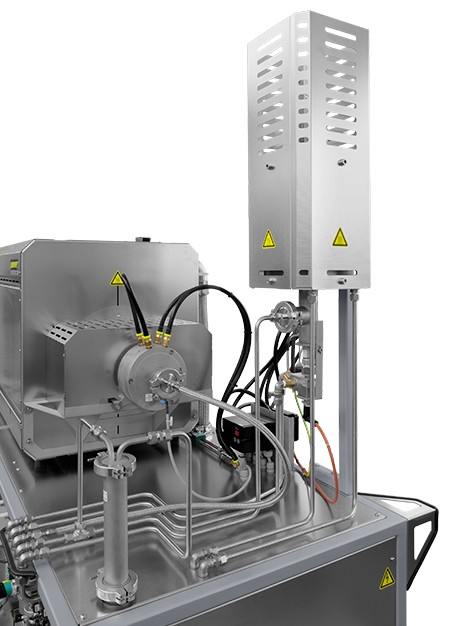

These compact tube furnaces are used when laboratory experiments must be performed horizontally, vertically, or at specific angles. The ability to configure the angle of tilt and the working height, and their compact design, also make these tube furnaces suitable for integration into existing process systems.

Standard Equipment

- Tmax 1100 °C, 1300 °C, or 1500 °C

- Compact design

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Vertical or horizontal operation infinitely adjustable

- Angle infinitely adjustable from 0 to 90

- Working height infinitely adjustable

- Operation also possible without stand if safety guidelines are observed

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Type S thermocouple

- Solid state relays provide for lownoise operation

- Heating wires wound directly around the working tube resulting in very fast heat-up rates

- Control system integrated in furnace base

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller B510 (5 programs with each 4 segments)

Additional equipment

Additional Equipment

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Gas supply system 1 for non-flammable protective or reactive gas

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

| Model | Tmax1 | Outer dimensions2 in mm | Inner tube Ø | Heated | Length constant | Tube length | Connected | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

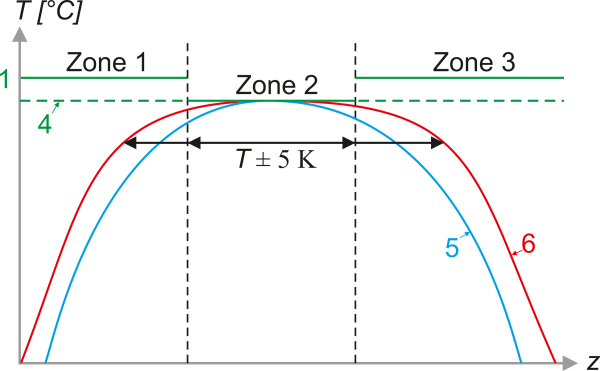

| in °C | W | D | H | in mm | length in mm | temperature1 +/− 5 K in mm | in mm | load in kW | connection* | in kg | |

| RT 50/250/11 | 1100 | 350 | 380 | 740 | 50 | 250 | 80 | 360 | 1.8 | 1-phase | 25 |

| RT 50/250/13 | 1300 | 350 | 380 | 740 | 50 | 250 | 80 | 360 | 1.8 | 1-phase | 25 |

| RT 30/200/15 | 1500 | 445 | 475 | 740 | 30 | 200 | 70 | 360 | 1.8 | 1-phase | 45 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K*Please see page 75 for more information about supply voltage 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

|||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnaces, ovens and accessories for the laboratory can be found in our “Laboratory” catalog.