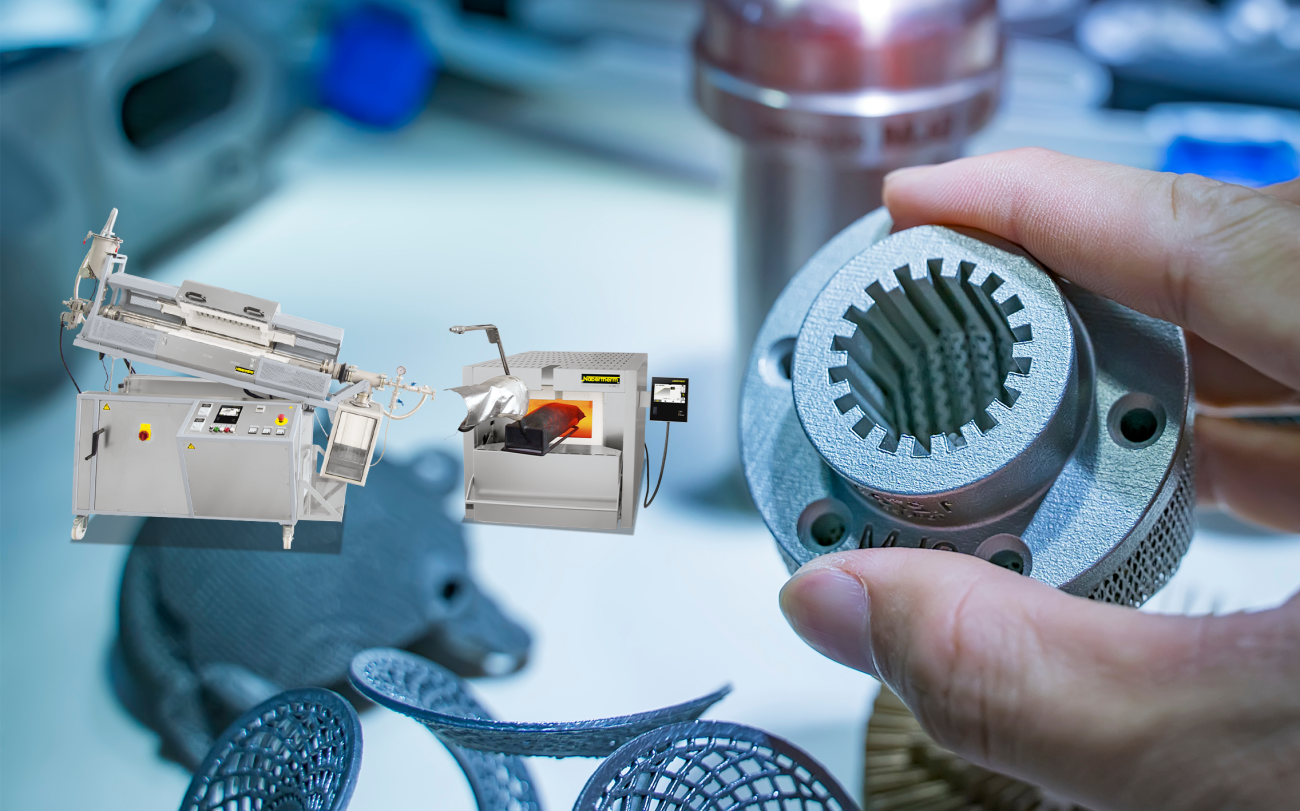

The transportable bale-out furnaces of the TM product lines were developed especially for use at different pouring locations. The cylindrical, very stable furnace housing, the very high-quality insulation and the meander-shape heating elements are the special features of this furnace family. The furnaces are designed to be transported by forklift truck and come with a plug-in connection to the control gear. With a forklift truck the furnace can be transported to the pre-melt furnace for filling. Due to the filling of the bale-out furnace directly at the premelting furnace, the otherwise necessary intermediate transport by means of a transport ladle and an additional filling process can be omitted. This has a positive effect on both energy efficiency and melt quality.

- Tmax 1000 °C, ideal for holding of aluminum alloys

- Cylindrical, highly stable furnace housing

- Damper slots under the furnace for safe forklift transportation of the furnace with the melt inside the foundry

- All-round heating provided by meander-shape heating elements

- Plug connection on the furnace for easy disconnection of the connecting cable to the switchgear

- Heating controlled using long-lasting solid-state-relays

- Insulation constructed in multiple layers with lightweight refractory bricks on the hot face

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Emergency outlet for safe discharge of the melt in case of a crucible break

- No exhaust gas vent necessary

- Crucible in standard design not included

- Over-temperature limiter in furnace chamber for protection against overheating. The limiter switches the heating off when the set limit temperature is reached, and only switches it back on after the temperature has fallen again.

- Low-maintenance furnace chamber control with temperature measurement behind the crucible

- Defined application within the constraints of the operating instructions