機能と設備

Fusing furnace F 30

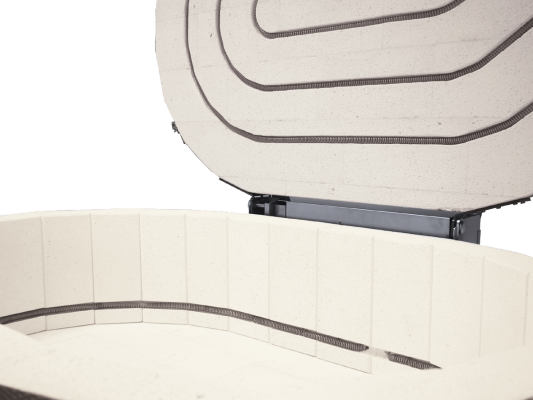

Robust lid construction with two lid brackets

Interior with bottom side ring heating on fusing furnaces F 75 – F 220

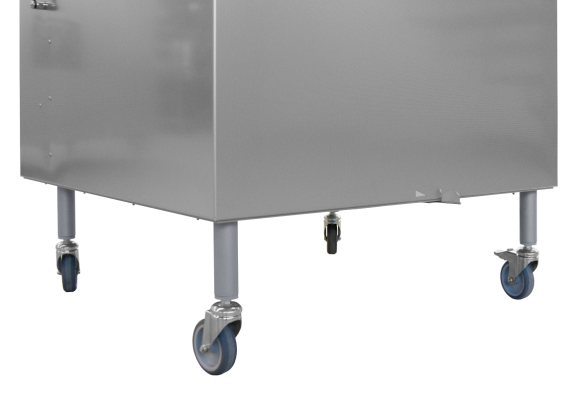

Sturdy professional-grade castors on fusing furnaces F 75 – F 220

This kiln range is the ideal choice for many fusing applications. The insulation is made from lightweight refractory bricks with protected heating elements in the lid, fusing furnaces F 75 and F 220 have additional side heating.

Standard Equipment

- Housing made of textured stainless steel

- Controller mounted on the right side of the kiln with removable holder for comfortable operation

- Insulation made of lightweight refractory bricks for clean firing results

- Lid with adjustable quick-release lock and padlock hasp

- Adjustable lid mechanism

- Long-life lid seal (brick on brick)

- Lid interlock safety switch

- Heating elements in the lid, fusing furnaces F 75 and F 220 have additional side heating

- Solid state relays provide for low-noise operation

- Powerful gas springs support lid opening

- Lockable castors for easy transport of kiln without the need for lifting (F 75 - F 220)

- Top loader F 30 as tabletop model without castors

- Manual-Zone-Regulation for F 220 (lid and sides)

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation C540 (10 programs with each 20 segments) resp. P570 (50 programs with each 40 segments) for F 220

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

付加装置

Additional equipment

- Higher chassis

技術仕様

| Model | Tmax | Inner dimensions in mm | Floor space in | Outer dimensions2 in mm | Connected load | Electrical | Weight in | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | m2 | W | D | H | kW | connection | kg | |

| F 30 | 950 | Ø 410 | 230 | 0.13 | 650 | 800 | 500 | 2.0 | 1-phase | 50 | |

| F 75 L | 950 | 750 | 520 | 230 | 0.33 | 950 | 880 | 680 | 3.6 | 1-phase | 80 |

| F 75 | 950 | 750 | 520 | 230 | 0.33 | 950 | 880 | 680 | 5.5 | 3-phase | 80 |

| F 110 LE | 950 | 930 | 590 | 230 | 0.47 | 1120 | 950 | 680 | 6.0 | 1-phase1 | 95 |

| F 110 | 950 | 930 | 590 | 230 | 0.47 | 1120 | 950 | 680 | 7.5 | 3-phase | 115 |

| F 220 | 950 | 930 | 590 | 460 | 0.47 | 1120 | 950 | 910 | 15.0 | 3-phase | 175 |

| 1Fusing of 32 A if connected to 230 V 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request |

|||||||||||