機能と設備

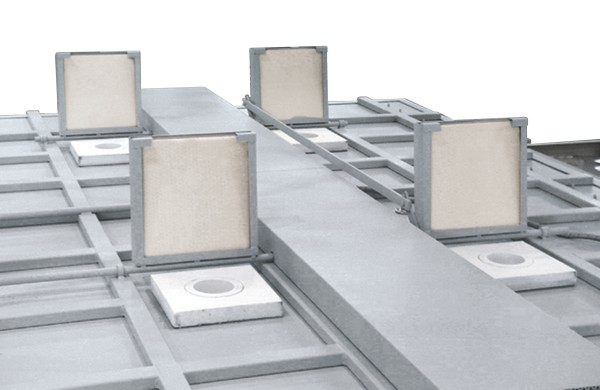

Top hat furnace HG 5208/S with two tables for bending and slumping of glass

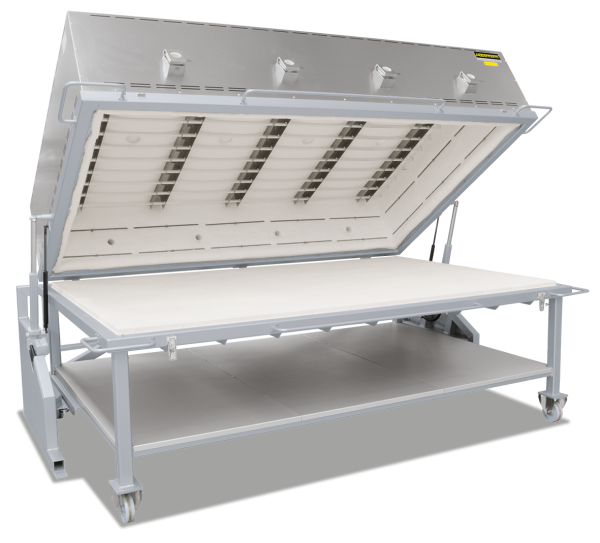

Top hat furnace HG 1196/S with top hat and table heating; table heating can be switched-off during fusing

Top hat furnace HG 2000

Motorized exhaust air flaps as additional equipment

Heating elements in furnace hood

Fiber insulation covered with fabric to reduce dust in the furnace

Nabertherm markets this range of top hat furnaces for bending and slumping of large glass parts. The top hat furnace is equipped with one table running on rails which can be pulled out for easy charging. As accessory an additional table can be integrated, which is charged while the other table is in the furnace. The top hat furnaces are heated from the ceiling and from the table.

- Tmax 900 °C

- Heating from lid and table

- 3-zone temperature control (lid-inner circular element, lid-outer circular element, table) for optimal temperature uniformity

- Table heating can be switched-off for fusing

- Heating elements on supporting tubes provide for long service life

- Table heating elements covered by SiC tiles for level stacking support

- Top hat insulated with high-quality fiber material; exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Table insulated with multi-layer resistant, lightweight refractory bricks

- Top hat to be opened by overhead crane in floor shop

- Protection guides for easy top hat opening and closing

- Manually-operated exhaust air flap

- Furnace table on fixed chassis for user-friendly charging height (approx. 800 mm)

- Defined application within the constraints of the operating instructions

- NTLog for Nabertherm Controller: Recording of process data with USB-flash drive

- Controller P570 (50 programs with each 40 segments)

付加装置

- Top hat side heating in case of high top hat dimensions

- Design without table heating or with disengageable table heating for fusing

- Electro-hydraulically driven top hat

- Motorized exhaust air flap for faster cooling of the fusing furnace

- Cooling system to assist cooling the furnace below the quartz inversion

- Table on wheels for free movement

- Interchangeable table system running on rails: to shorten process times and optimise operational capacity, two or more tables, placed alternately under the hood, can be used. An automatic table changing system is also available on request.

- Process control and documentation via Nabertherm Control Center (NCC) for monitoring, documentation and control

技術仕様

| Model | Tmax | Inner dimensions in mm | Floor space | Outer dimensions2 in mm | Heating power | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in m2 | W | D | H | in kW1 | connection | in kg | |

| HG 750 | 900 | 2100 | 1200 | 300 | 2.52 | 2550 | 1800 | 1350 | 35 | 3-phase | 1200 |

| HG 1000 | 900 | 1750 | 1000 | 550 | 1.75 | 2200 | 1450 | 1600 | 33 | 3-phase | 1500 |

| HG 1500 | 900 | 2100 | 1250 | 550 | 2.63 | 2550 | 1700 | 1600 | 44 | 3-phase | 2000 |

| HG 1800 | 900 | 2450 | 1850 | 400 | 4.35 | 2950 | 2350 | 1600 | 45 | 3-phase | 2500 |

| HG 2000 | 900 | 2450 | 1500 | 550 | 3.68 | 2900 | 1950 | 1600 | 55 | 3-phase | 2500 |

| HG 2640 | 900 | 3000 | 2200 | 400 | 6.60 | 3500 | 2700 | 1450 | 75 | 3-phase | 3400 |

| HG 3000 | 900 | 3500 | 2200 | 400 | 7.70 | 4000 | 2800 | 1600 | 75 | 3-phase | 3800 |

| HG 4800 | 900 | 5500 | 2100 | 400 | 11.55 | 6000 | 2700 | 1600 | 90 | 3-phase | 4500 |

| HG 5208/S | 900 | 3100 | 2100 | 800 | 6.51 | 3990 | 2590 | 3140 | 110 | 3-phase | 5000 |

| HG 7608/S | 900 | 3800 | 2500 | 800 | 9.50 | 4690 | 2990 | 3140 | 143 | 3-phase | 7000 |

| 1Depending on furnace design connected load might be higher 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request |

|||||||||||