機能と設備

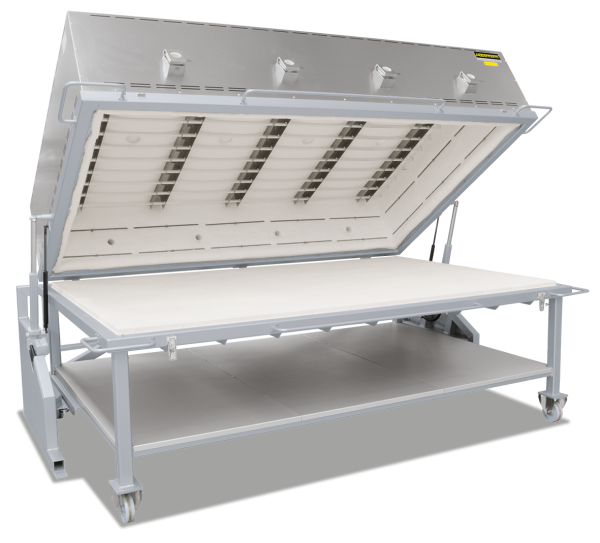

Tub furnace GW 1660

Tub furnace GW 2200

Top hat furnace GW 2208/S with electro-hydraulically driven hood, tub can be pulled out on rails

Automatic lid opening via electromechanical spindle

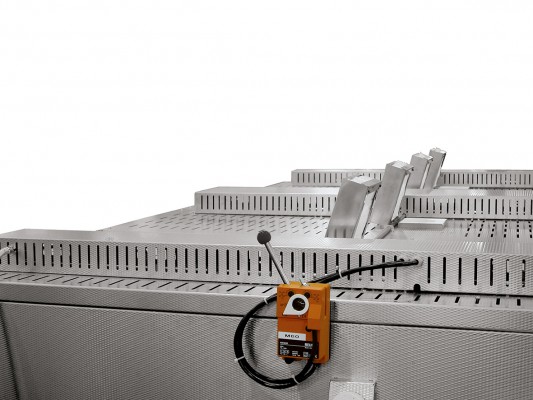

Motorized exhaust air flaps as additional equipment

Bottom heating covered by SiC tiles to create level stacking support

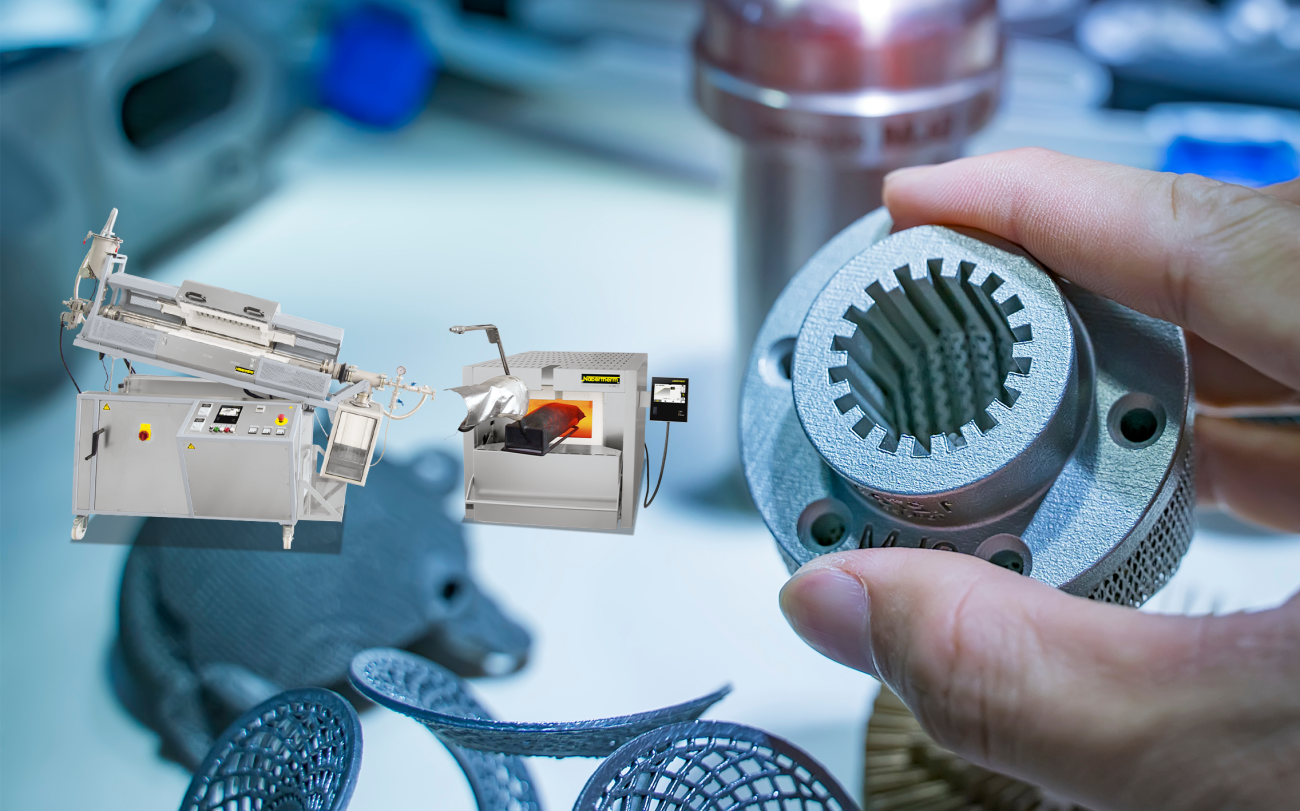

For slumping and bending of complex glass parts, e. g. glass furniture, shower cabins, etc., tub furnaces are the right choice. Full coverage heating: from the lid, all 4 sides and the tub bottom. Due to the modular system additional tubs in customized dimensions can be provided.

- Tmax 900 °C

- Full coverage heating: from lid, all 4 sides and bottom

- 3-zone temperature control from top to bottom for optimal temperature uniformity

- Heating elements mounted on ceramic support tubes for free heat radiation and long service life

- Bottom heating covered by SiC tiles

- Top hat insulated with high-quality fiber material; exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Manual hinged lid with gas struts for easy opening and closing

- Manually operated exhaust air flaps

- Tub on wheels can be pulled out manually

- Rails on floor for perfect tub guidance included

- Defined application within the constraints of the operating instructions

付加装置

- Electro-hydraulic lid instead of manual hinged lid

- Tub insert to elevate bottom height, in order to use the furnace for glass fusing applications (in this product version the tub heating can be switched off

- Automatic lid opening, can be programmed using the extra function of the controller, for faster cooling

- Motorized exhaust air flap for faster cooling

- Cooling system to assist cooling the furnace below the quartz inversion

- Interchangeable table system running on rails: to shorten process times and optimise operational capacity, two or more furnace tubs, placed alternately under the hood, can be used. An automatic tub changing system is also available on request.

- Process control and documentation via Nabertherm Control Center (NCC) for monitoring, documentation and control

技術仕様

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | power in kW1 | connection | in kg | |

| GW 830 | 900 | 1200 | 1150 | 600 | 830 | 2140 | 1980 | 1250 | 36 | 3-phase | 820 |

| GW 840 | 900 | 1650 | 850 | 600 | 840 | 2590 | 1680 | 1250 | 36 | 3-phase | 980 |

| GW 1200 | 900 | 2000 | 1000 | 600 | 1200 | 2940 | 1830 | 1250 | 40 | 3-phase | 1210 |

| GW 1500 | 900 | 2100 | 1150 | 600 | 1450 | 3040 | 1980 | 1250 | 70 | 3-phase | 1420 |

| GW 1660 | 900 | 2300 | 1200 | 600 | 1660 | 3240 | 2030 | 1250 | 80 | 3-phase | 1780 |

| GW 2200 | 900 | 2300 | 1200 | 800 | 2200 | 3240 | 2030 | 1400 | 90 | 3-phase | 2160 |

| GW 8000 | 900 | 3700 | 2700 | 800 | 8000 | 4640 | 3530 | 1400 | 180 | 3-phase | 2980 |

| 1Depending on furnace design connected load might be higher 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request |

|||||||||||