Печи для озоления с интегрированной системой очистки отработанных газов до 1100 °C

Печи для озоления оснащены пассивной системой безопасности и интегрированной системой нейтрализации ОГ

Функции и оборудование

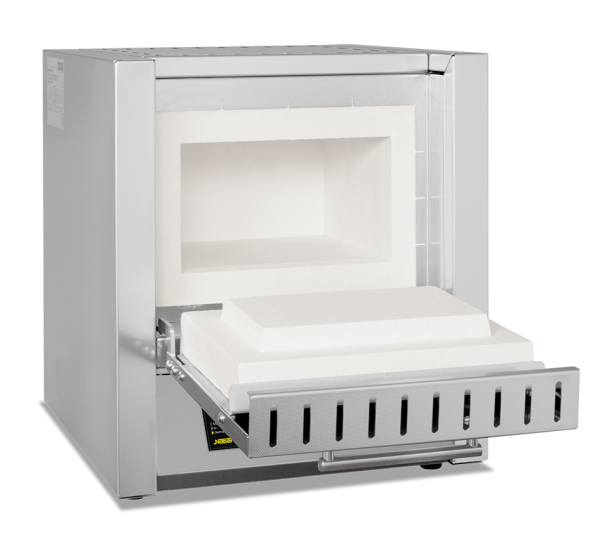

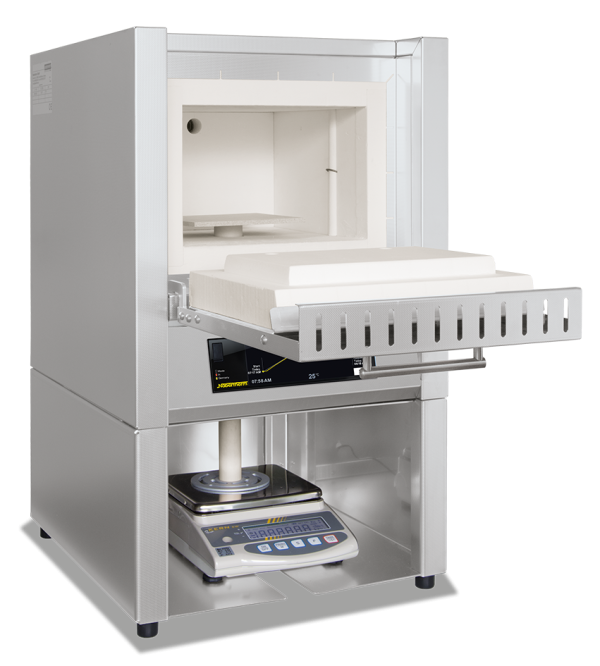

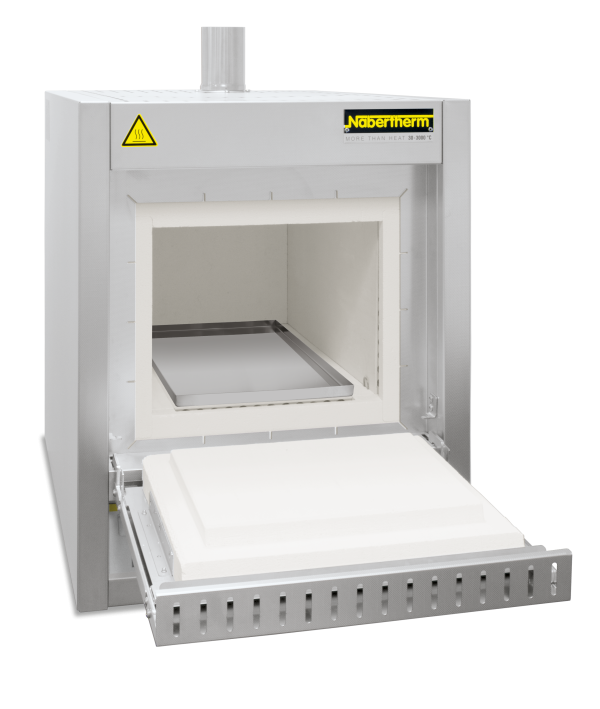

The ashing furnaces L ../11 BO are specially designed for processes in which organic substances have to be evaporated from the charge, as e. g. during debinding of small ceramic products after additive manufacturing. Other processes, for which this furnace series is designed for, are for example, ashing of (food) samples, thermal cleaning of injection molding tools or loss on ignition determination.

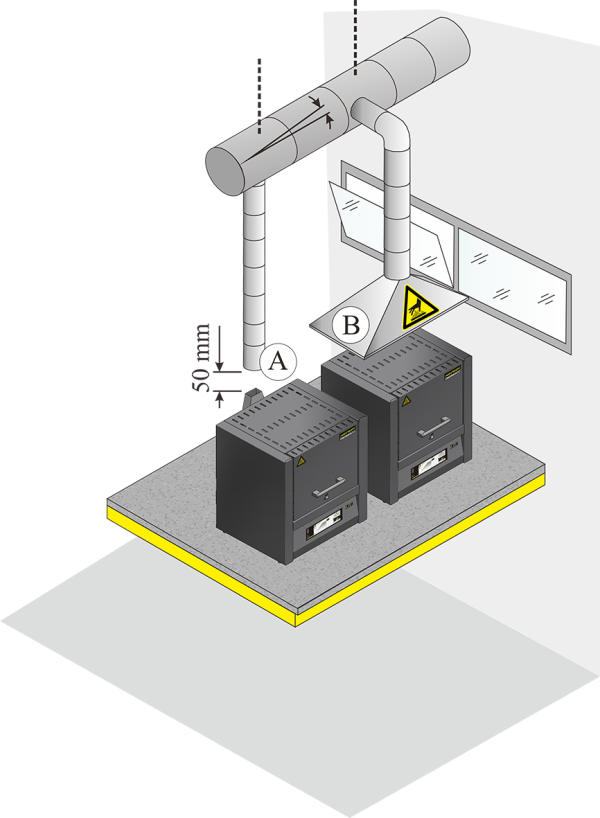

The ashing furnaces therefore have a passive safety system and integrated exhaust gas post combustion. An exhaust gas fan extracts the exhaust gases from the furnace and simultaneously supplies fresh air to the furnace atmosphere with the result that sufficient oxygen is always available for the process. The incoming air is guided behind the furnace heating and preheated to ensure good temperature uniformity. Exhaust gases are directly led from the furnace chamber to the integrated post combustion system, where they are burned and catalytically cleaned. After the debinding/ashing process (up to max. 600 °C), a sintering process up to max. 1100 °C can be performed.

Standard Equipment

- Tmax 600 °C for the incineration process

- Tmax 1100 °C for the subsequent process

- Three-side heating (both sides and bottom)

- Ceramic heating plates with embedded heating wire

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Steel collecting pan protects the bottom insulation

- Spring-assisted closing of the furnace door (flap door) with mechanical locking against unintentional opening

- Thermal/catalytic post combustion, integrated in the exhaust channel, up to 600 °C in function

- Temperature control of post combustion can be set up to 850 °C

- Monitored exhaust air

- Inlet-air preheated through the bottom heating plate

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Controller with touch operation C550 (10 programs with each 20 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Дополнительное оборудование

Additional Equipment

- Process control and documentation via VCD software package for monitoring, documentation and control

Спецификации

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Max. loading weight of organic substances | Max. evaporation rate of organic substances | Connected load | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

in °C1 | w | d | h | in l | W | D | H3 | in g | g/min | in kW | connection | in kg | |

L 9/11 BO | 1100 | 230 | 240 | 170 | 9 | 415 | 575 | 750 | 75 | 1.0 | 7.0 | 3-phase | 60 |

L 24/11 BO | 1100 | 280 | 340 | 250 | 24 | 490 | 675 | 800 | 150 | 2.0 | 9.0 | 3-phase | 90 |

L 40/11 BO | 1100 | 320 | 490 | 250 | 40 | 530 | 825 | 800 | 200 | 2.1 | 11.5 | 3-phase | 110 |

1Recommended working temperature for processes with longer dwell times is 1000 °C | |||||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента печей, сушильных шкафов и принадлежностей для лабораторных помещений вы найдете в нашем каталоге «Лаборатория».