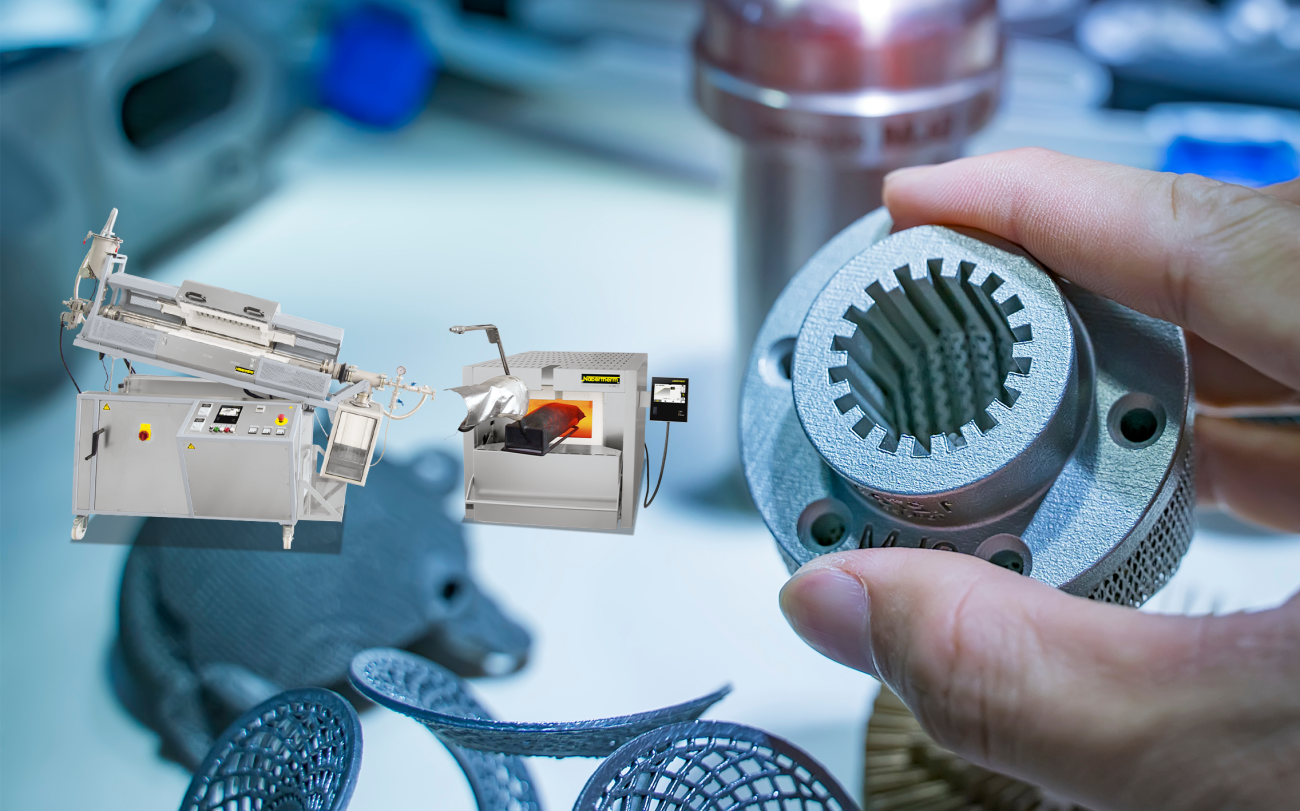

For casting with lost patterns, among other things, furnaces are needed to get the pattern material out of the mold in a safe way and to fire the mold. Nabertherm also offers different solutions for this.

Dewaxing Furnaces, Electrically Heated

These furnaces are specially designed for lost wax melting with subsequent firing of the ceramic mold. The electrically heated models are operated below the flash point of the wax for lost wax melting. The furnaces have a heated outlet in the bottom of the furnace chamber, which tapers to the center in a funnel shape. Below the furnace is a sealed stainless steel container with a removable drawer in which the wax is collected. After completion of the melting out process, the furnace continues to heat up to fire the molds.

Dewaxing Furnaces, Gas-Fired

The chamber furnaces of the NB .. BOWAX are suitable for flash-fire processes in which the hot furnace is loaded with casting screws. For fast loading and unloading, the furnace is equipped with a pneumatic lift door. After loading, the wax liquefies in a very short time. The first part of the outflowing wax runs via the integrated pan directly into a collecting basin under the furnace and is safely collected in a water basin. The remaining part of the wax evaporates in the furnace chamber and is safely burned in the downstream thermal afterburning.

Burnout of Residual Wax or 3D-Printed Plastic Models

The chamber furnaces of the series N(B) .. BO are used for processes with high organic quantities or high evaporation rates. For safety reasons, they have an integrated pilot burner for ignition of the flammable components in mixed gases. An accumulation of ignitable components is avoided and safe burning is ensured. These furnaces can be used for residual dewaxing of casting screws or burnout of 3D-printed plastic models with subsequent sintering of the mold.

For detailed information, please also see our catalog Advanced Materials.