Funkcja i wyposażenie

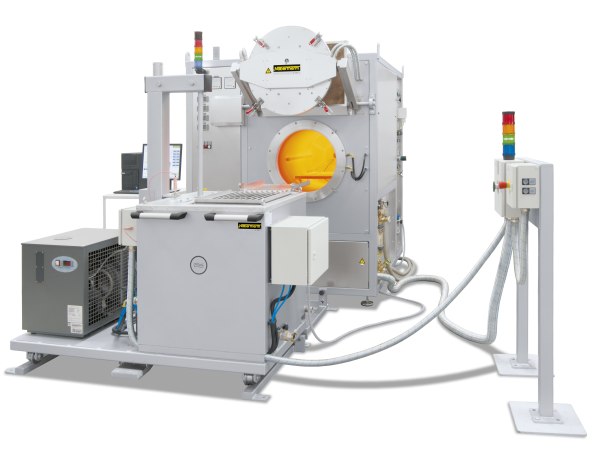

The retort furnaces SR and SRA (with gas circulation) are designed for operation under non-flammable or flammable protective or reaction gases. The hot-wall retort furnaces are loaded from above by crane or other lifting equipment provided by the customer. In this way, even large charge weights can be loaded into the furnace chamber.

Depending on the temperature range in which the furnace be used, the following models are available:

Models SRA ../06 with Tmax 650 °C

- Heating inside the retort

- Gas-circulation with powerful fan in the furnace lid

- Temperature uniformity up to +/- 5 °C inside the work space

- Single-zone control

- Retort made of 1.4571

- Insulation made of high-grade mineral wool

Models SRA ../09 with Tmax 900 °C

- Design like models SR…/06 with following differences:

- All-around heating from outside of the retort

- Only fiber materials are used which are not classified as carcinogenic according to TRGS 905, class 1 or 2

- Retort made of 1.4828

Models SR .../11 with Tmax 1100 °C

- Design like models SR…/09 with following differences:

- Without gas-circulation

- Top down multi-zone control of the furnace heating

- Retort made of 1.4841

Standard Equipment (all models)

- Design like standard equipment of models NR and NRA with following differences: see control alternative page 71

- Compact housing in frame construction with inserted stainless steel sheets

- Charging from above with crane or other lifting equipment from customer

- Hinged lid with opening to the side

- Welded charging frame resp. gas-guiding box for furnaces with circulation

- Gas-supply system for one non-flammable protective or reactive gas with flowmeter and magnetic valve

- Furnace temperature control

- Possible connection of an optional vacuum pump (for cold evacuation or for processes up to 600 °C under vacuum)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment, H2 version or IDB version see models NR and NRA

Specyfikacja techniczna

| Model | Tmax | Inner dimensions of alloy retort | Volume | Outer dimensions1 in mm | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|

| °C | Ø in mm | h in mm | in l | W | D | H | connection | in kg | |

| SR(A) 17/.. | 250 | 350 | 17 | 1300 | 1700 | 1800 | 3-phase | 600 | |

| SR(A) 25/.. | 250 | 500 | 25 | 1300 | 1900 | 1800 | 3-phase | 800 | |

| SR(A) 50/.. | 400 | 450 | 50 | 1400 | 2000 | 1800 | 3-phase | 1300 | |

| SR(A) 100/.. | 650, | 400 | 800 | 100 | 1400 | 2000 | 2100 | 3-phase | 1500 |

| SR(A) 200/.. | 900 | 600 | 700 | 200 | 1600 | 2200 | 2200 | 3-phase | 2100 |

| SR(A) 300/.. | or | 600 | 1000 | 300 | 1600 | 2200 | 2500 | 3-phase | 2400 |

| SR(A) 500/.. | 1100 | 800 | 1000 | 500 | 1800 | 2400 | 2700 | 3-phase | 2800 |

| SR(A) 600/.. | 800 | 1200 | 600 | 1800 | 2400 | 2900 | 3-phase | 3000 | |

| SR(A) 800/.. | 1000 | 1000 | 800 | 2000 | 2600 | 2800 | 3-phase | 3100 | |

| SR(A) 1000/.. | 1000 | 1300 | 1000 | 2000 | 2600 | 3100 | 3-phase | 3300 | |

| SR(A) 1500/.. | 1200 | 1300 | 1500 | 2200 | 2800 | 3300 | 3-phase | 3500 | |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. | |||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

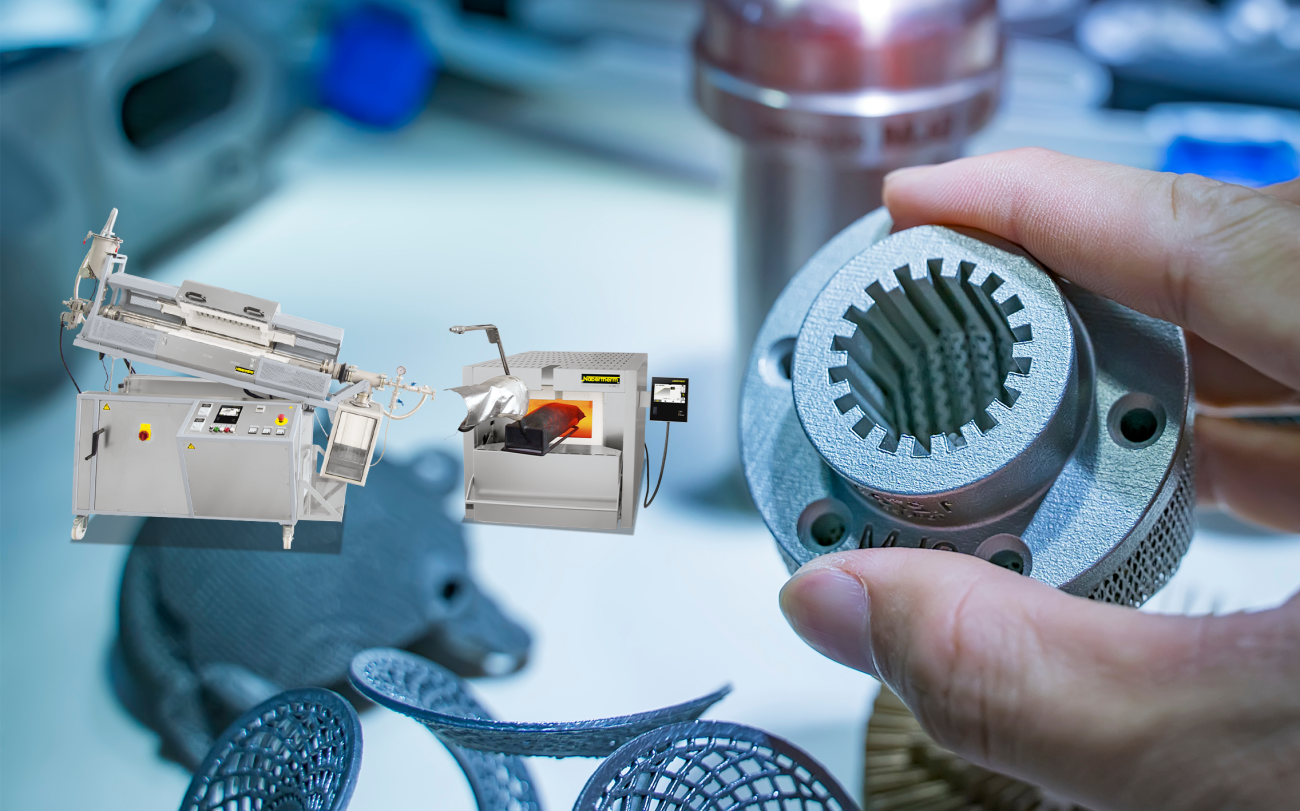

Kompletny przegląd naszej szerokiej oferty pieców i akcesoriów przeznaczonych do różnych procesów prowadzonych w atmosferze gazów reakcyjnych palnych i niepalnych, w kąpieli solnej lub w próżni można znaleźć w naszym katalogu „Technologia procesów termicznych II”.