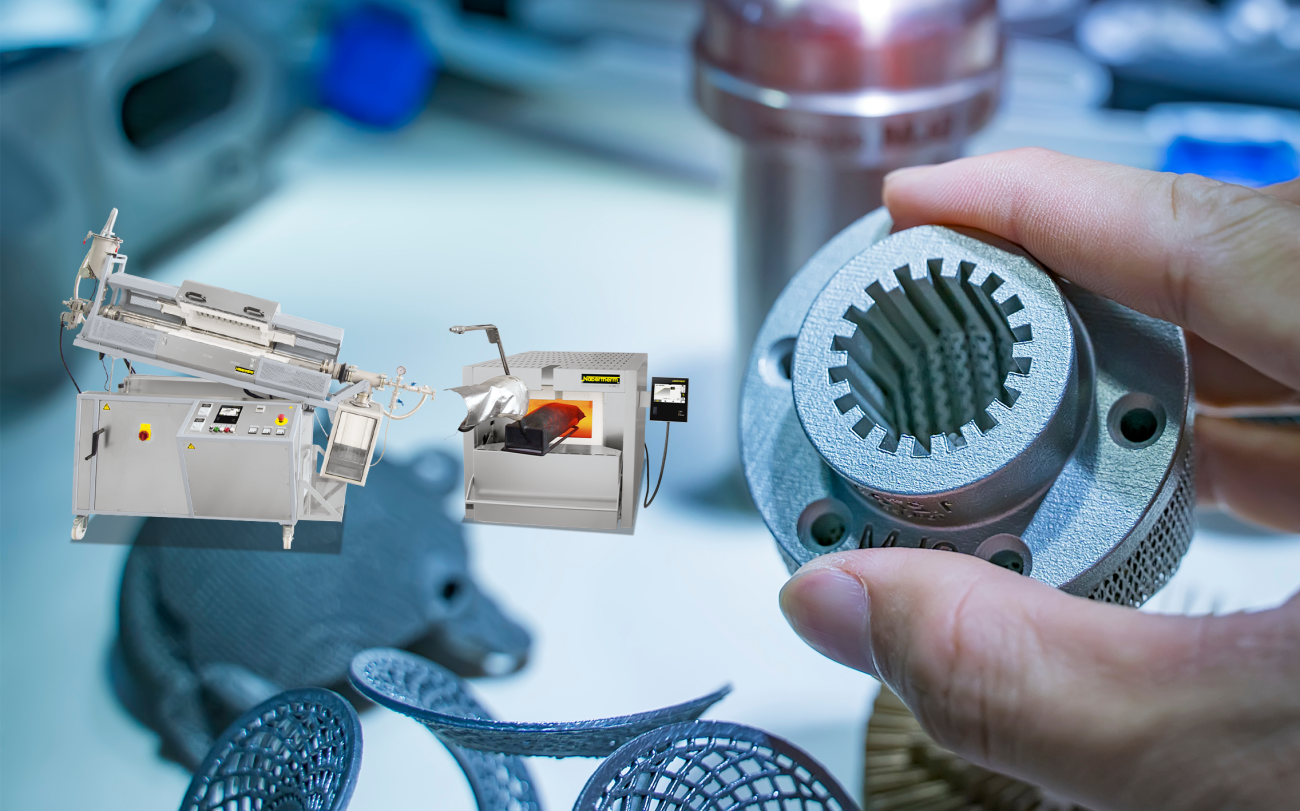

Cold-Wall Retort Furnaces up to 2400 °C Under Hydrogen

In the H2 version the retort furnaces can be operated under hydrogen or other reaction gases.

In the H2 version the retort furnaces can be operated under hydrogen or other reaction gases.

What furnace is the right choice for this specific process? This question cannot always be answered easily. Therefore, we have set up our modern test center which is unique in respect to size and variety. A representative number of furnaces is available for tests for our customers.