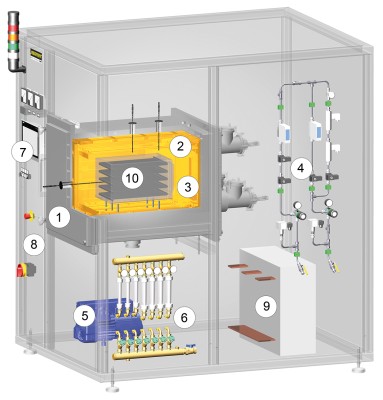

Function and equipment

The compact retort furnaces of the VHT product line are available as electrically heated chamber furnaces with graphite, molybdenum, tungsten or MoSi2 heating. A wide variety of heating designs as well as a complete range of accessories provide for optimal retort furnace configurations even for sophisticated applications.

The vacuum-tight retort allows heat treatment processes either in protective and reaction gas atmospheres or in a vacuum, subject to the individual furnace specs to 10-5 mbar. The basic furnace is suited for operation with non-flammable protective or reactive gases or under vacuum. The H2 version provides for operation under hydrogen or other flammable gases. Key of the specification up is a certified safety package providing for a safe operation at all times and triggers an appropriate emergency program in case of failure.

Alternative Heating Specifications

In general the following variants are available with respect to the process requirements:

VHT ../..-GR with Graphite Insulation and Heating

- Suitable for processes under protective and reaction gases or under vacuum

- Tmax 1800 °C, 2200 °C or 2400 °C (VHT 40/.. - VHT 100/..)

- Max. vacuum up to 10-4 mbar depending on pump type used

- Graphite felt insulation

VHT ../..-MO or VHT ../..-W with Molybdenum or Tungsten Heating

- Suitable for high-purity processes under protective and reaction gases or under high vacuum

- Tmax 1200 °C, 1600 °C or 1800 °C (see table)

- Max. vacuum up to 10-5 mbar depending on pump type used

- Insulation made of molybdenum rsp. tungsten radiation sheets

VHT ../..-KE with Fiber Insulation and Heating through Molybdenum Disilicide Heating Elements

- Suitable for processes under protective and reaction gases, in air or under vacuum

- Tmax 1800 °C

- Max. vacuum up to 10-2 mbar (up to 1300 °C) depending on pump type

- Insulation made of high purity aluminum oxide fiber

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

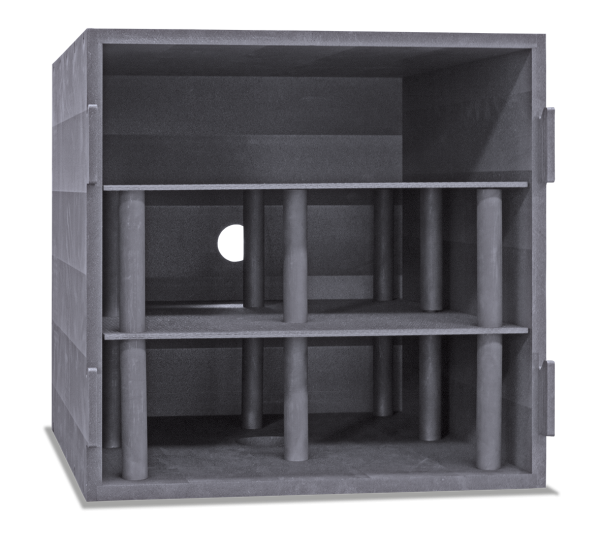

Basic version

- Standard furnace sizes 8 - 500 liters

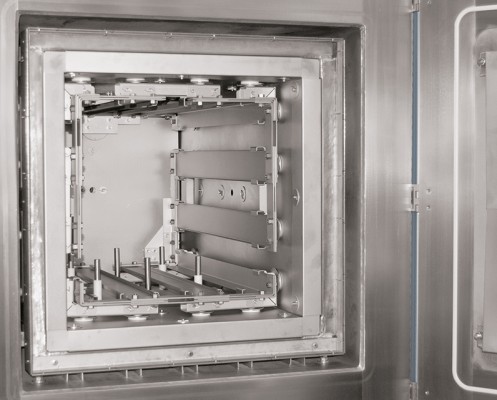

- Water-cooled retort made of stainless steel

- Frame made of stable steel profiles, easy to service due to easily removable stainless steel panels

- Housing of the VHT 8 model on castors for easy repositioning of furnace

- Cooling water manifold with manual tap, automatic flow monitoring, open-loop cooling water system

- Adjustable cooling water circuits with flowmeter and temperature indicator and overtemperature protection

- Switchgear and controller integrated in furnace housing

- Process control with controller P570

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Manual operation of the process gas and vacuum functions

- Manual gas supply for one process gas (N2, Ar or non-flammable forming gas) with adjustable flow

- Bypass with manual valve for rapid filling or flooding of furnace chamber

- Manual gas outlet with overflow valve (20 mbar relative) for over-pressure operation

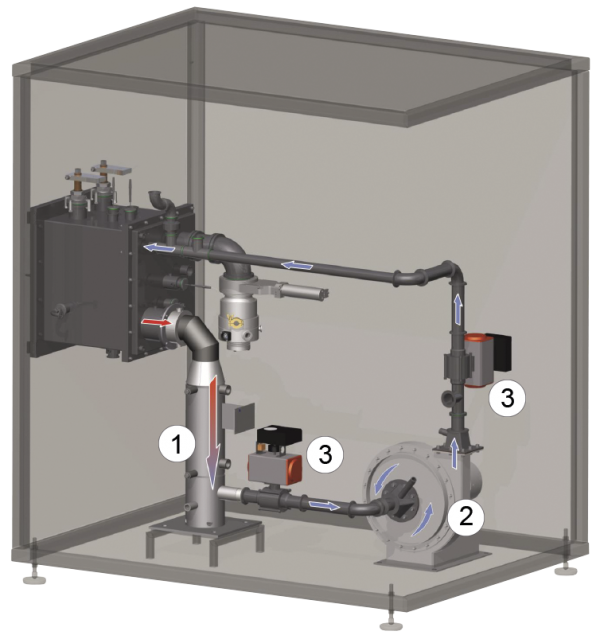

- Single-stage rotary vane pump with ball valve for pre-evacuating and heat treatment in a rough vacuum to 5 mbar

- Pressure gauge for visual pressure monitoring

- Defined application within the constraints of the operating instructions

Additional equipment

Additional equipment gas management system

- Manual gas supply for second process gas (N2, Ar or non-flammable forming gas) with adjustable flow and bypass

- Mass flow controller for alternating volume flow and generation of gas mixtures with second process gas (only with automation package)

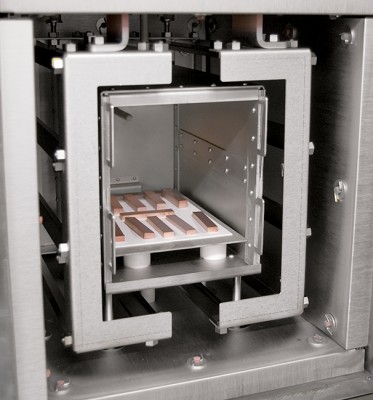

- Inner process box made of molybdenum, tungsten, graphite or CFC, especially recommended for debinding processes. The box is installed in the furnace with direct gas inlet and outlet and provides for better temperature uniformity. Generated exhaust gases will be directly lead out the inner process chamber during debinding. The change of gas inlet pathes after debinding results in a clean process gas atmosphere during sintering.

Additional equipment vacuum

- Two-stage rotary vane pump with ball valve for pre-evacuating and heat-treating in a fine vacuum (up to 10-2 mbar) incl. electronic pressure sensor

- Turbo molecular pump with slide valve for pre-evacuation and for heat treatment in a high vacuum (up to 10-5 mbar) including electronic pressure sensor and booster pump

- Other vacuum pumps on request

- Partial pressure operation: protective gas flushing at controlled underpressure (only with automation package)

Additional equipment cooling

- Heat exchanger with closed-loop cooling water circuit

- Direct cooling

Additional equipment for controls and documentation

- Charge thermocouple with display

- Temperature measurement at 2200 °C models with pyrometer in the upper temperature range and thermocouple, type C with automatic pull-out device for precise control results in the low temperature range (VHT 40/..-GR and larger)

- Automation package with process control H3700

- 12“ graphic touch panel

- Input of all process data like temperatures, heating rates, gas injection, vacuum at the touch panel

- Display of all process-relevant data on a process control diagram

- Automatic gas supply for one process gas (N2, argon or non-flammable forming gas) with adjustable flow

- Bypass for flooding and filling the chamber with process gas controlled by the program

- Automatic pre- and post programs, including leak test for safe furnace operation

- Automatic gas outlet with bellows valve and overflow valve (20 mbar relative) for over-pressure operation

- Transducer for absolute and relative pressure

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Technical specifications

| VHT ../..-GR | VHT ../..-MO | VHT ../18-W | VHT ../18-KE | |

|---|---|---|---|---|

| Tmax | 1800 °C, 2200 °C or 2400 °C | 1200 °C or 1600 °C | 1800 °C | 1800 °C |

| Inert gas | √ | √ | √ | √ |

| Air/Oxygen | - | - | - | √ |

| Hydrogen | √3,4 | √3 | √3 | √1,3 |

| Rough vacuum and fine vacuum (>10-3 mbar) | √ | √ | √ | √2 |

| High vacuum (<10-3 mbar) | √4 | √ | √ | √2 |

| Material of heater | Graphite | Molybdenum | Tungsten | MoSi2 |

| Material of insulation | Graphite felt | Molybdenum | Tungsten/Molybdenum | Ceramic fiber |

| 1Tmax reduces to 1400 °C 2Depending on the temperature 3Only with safety package for flammable gases 4Up to 1800 °C |

||||

| Model | Inner dimensions in mm | Volume | Max. charge | Outer dimensions6 in mm | Heating power in kW4 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| w | d | h | in l | weight/kg | W | D | H | Graphite | Molybdenum | Tungsten | Ceramic fiber | |

| VHT 8/.. | 170 | 240 | 200 | 8 | 5 | 1250 (800)1 | 1100 | 27005 | 27/27/-2 | 19/343 | 50 | 12 |

| VHT 25/.. | 250 | 400 | 250 | 25 | 20 | 1500 | 2500 | 2200 | 70/90/-2 | 45/653 | 85 | 25 |

| VHT 40/.. | 300 | 450 | 300 | 40 | 30 | 1600 | 26005 | 2300 | 83/103/1252 | 54/903 | 110 | 30 |

| VHT 70/.. | 375 | 500 | 375 | 70 | 50 | 18005 | 33005 | 2400 | 105/125/1502 | 70/1103 | 130 | 55 |

| VHT 100/.. | 450 | 550 | 450 | 100 | 75 | 1900 | 35005 | 2500 | 131/155/1752 | 90/1403 | on request | 85 |

| VHT 250/.. | 600 | 750 | 600 | 250 | 175 | 30001 | 4300 | 3100 | 180/210/-2 | on request | on request | on request |

| VHT 500/.. | 750 | 900 | 750 | 500 | 350 | 32001 | 4500 | 3300 | 220/260/-2 | on request | on request | on request |

| 1With separated switching system unit 21800 °C/2200 °C 31200 °C/1600 °C 4Depending on furnace design connected load might be higher 5Dimensions may be smaller depending on the heater type 6External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

||||||||||||

Request for quotation

Further products

Catalog

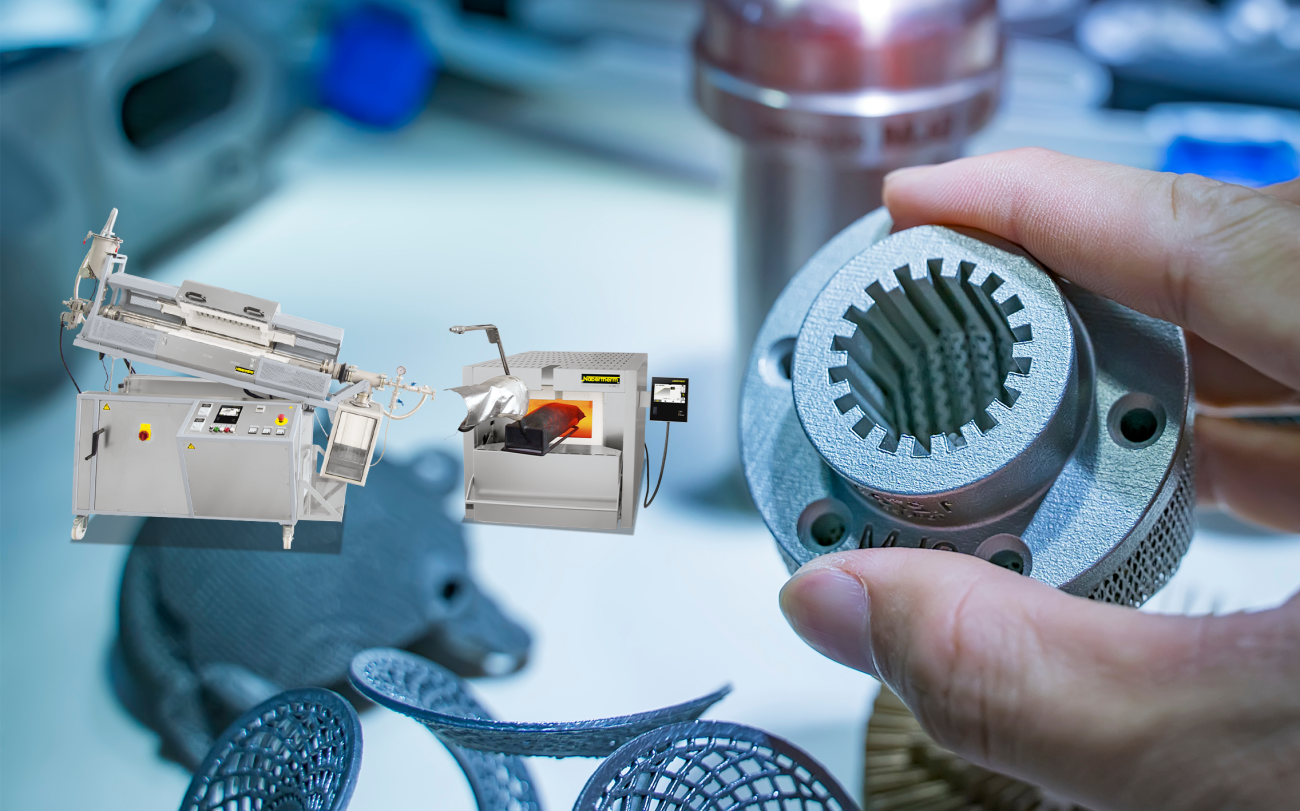

A complete overview of our extensive range of furnaces and accessories for various processes that take place under flammable or non-flammable reaction gases, in a salt bath or under vacuum can be found in our catalog "Thermal Process Technology II".