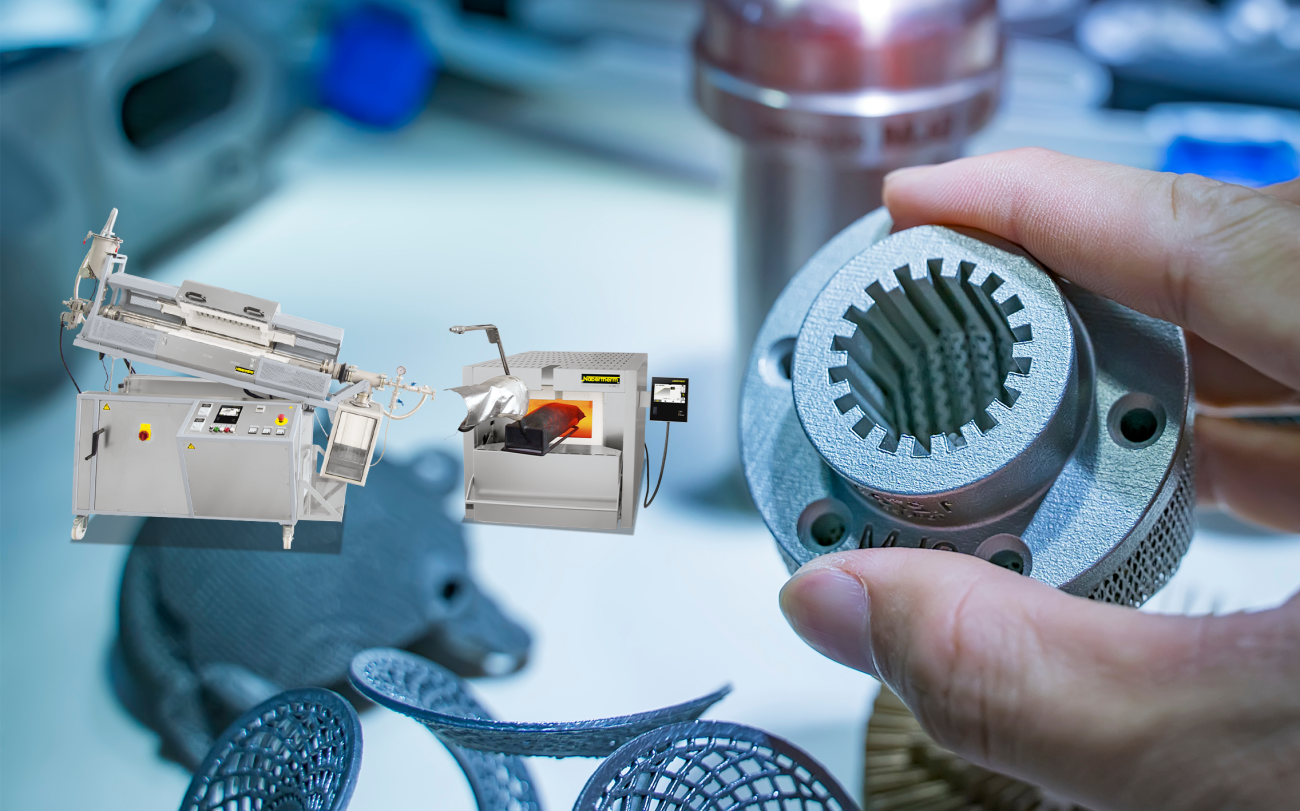

SVHT 2/24-W - SVHT 9/30-GR

Compared with the VHT models (page 62 ff), the retort furnaces of the SVHT product line offer improved performance data with regard to achievable vacuum and maximum temperature. Due to the design as pit-type furnace with tungsten heating, processes up to max. 2400 °C even in high vacuum can be implemented with models of the SVHT..-W product line. Models of the SVHT..-GR product line with graphite heating, also in pit-type design, can be operated in an inert gas atmosphere even up to max. 3000 °C.

- Standard sizes with a furnace chamber of 2 or 9 liters

- Designed as pit-type furnace, charged from above

- Frame construction with inserted sheets of textured stainless steel

- Dual shell water-cooled stainless steel container

- Manual operation of process gas and vacuum functions

- Manual gas supply for non-combustible process gas

- A step in front of the furnace for an ergonomic charging height

- Retort lid with gas-charged shock absorbers

- Controls and switchgear as well as gas supply integrated in furnace housing

- Defined application within the constraints of the operating instructions

- Further standard product characteristics see description for standard design of VHT models

Heating Options

SVHT ..-GR

- Applicable for processes:

- under protective or reaction gases or in the vacuum up to 2200 °C under consideration of relevant max. temperature limits

- under inert gas argon up to 3000 °C

- Max. vacuum up to 10-4 mbar depending on the type of pump used

- Heating: graphite heating elements in cylindrical arrangement

- Insulation: graphite felt insulation

- Temperature measurement by means of an optical pyrometer

SVHT ..-W

- Applicable for processes under protective or reaction gases or in vacuum up to 2400 °C

- Max. vacuum up to 10-5 mbar depending on the type of pump used

- Heating: cylindrical tungsten heating module

- Insulation: tungsten and molybdenum radiant plates

- Temperature measurement with thermocouple type C

- Additional equipment such as automatic process gas control or design for the operation with flammable gases incl. safety system see VHT models