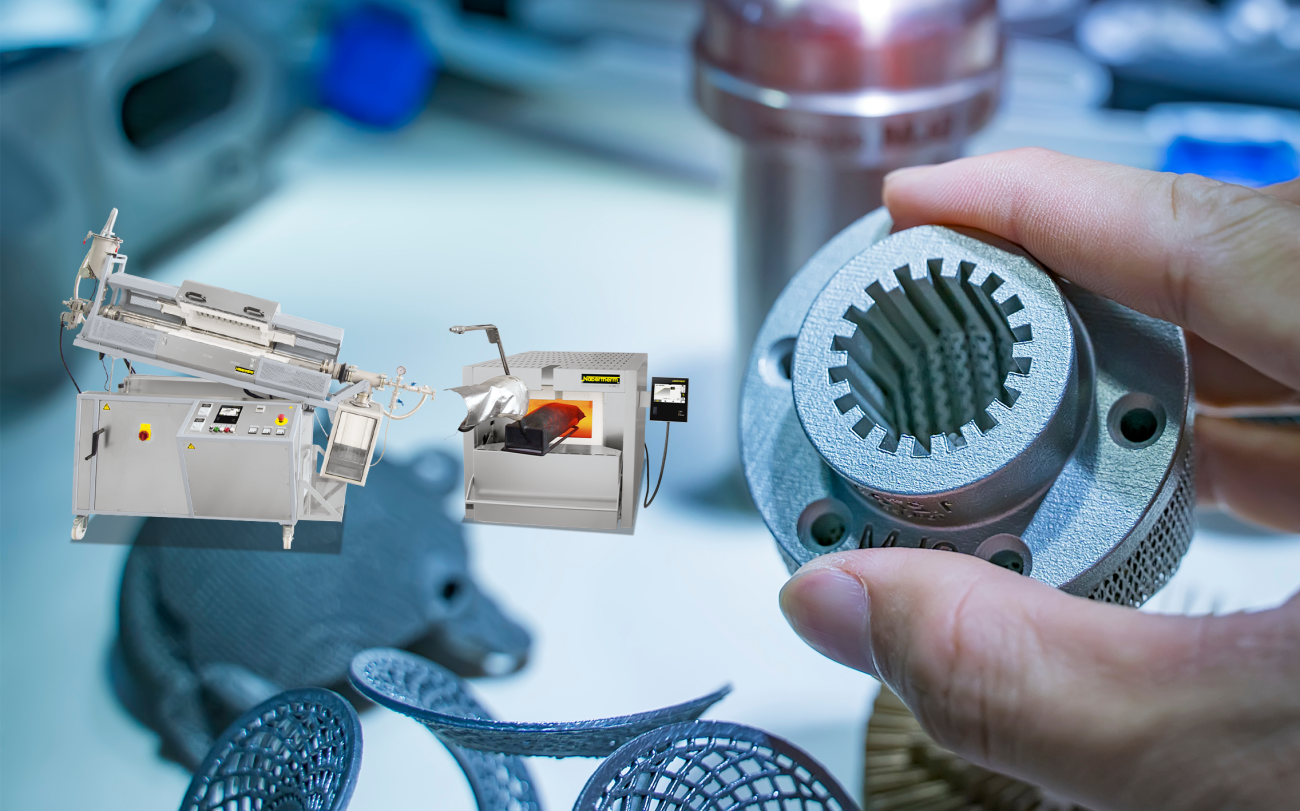

QS 20 - QS 400 martempering furnaces are filled with neutral salt and offer remarkably rapid and intensive heat transmission to the workpiece while ensuring optimum temperature uniformity. Since the batch is heat treated with the exclusion of oxygen, scale and discoloration on the surface of the parts are reduced to a minimum. For working temperatures at between 180 °C and 500 °C these martempering furnaces are useful for quenching or cooling with minimal workpiece distortion, retempering, austempering for optimal toughness, recrystallization annealing after electrical discharge machining (EDM) and for blueing. The quenching or cooling process is applied in order to achieve an even temperature uniformity throughout the workpiece‘s entire cross-section before the formation of martensite and to avoid distortion and formation of cracks in complex mechanical components during the subsequent hardening process. Tempering in a martempering bath is the same as the tempering process in forced convection furnace and is used to reduce a previously hardened workpiece to a desired hardness, to increase toughness and reduce stress within the workpiece. Austempering is a good choice to achieve a high level of toughness and dimensional accuracy in oil hardened low-alloy steels. Workpieces subject to austempering have high tensile strength and good elasticity.

- Tmax 550 °C

- Very good temperature uniformity

- Martemper bath temperature control

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Heating with immersion heating elements

- Rectangular crucible, integrated in the housing

- Charging basket

- Crucible made of 1.4828

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive