Funkcja i wyposażenie

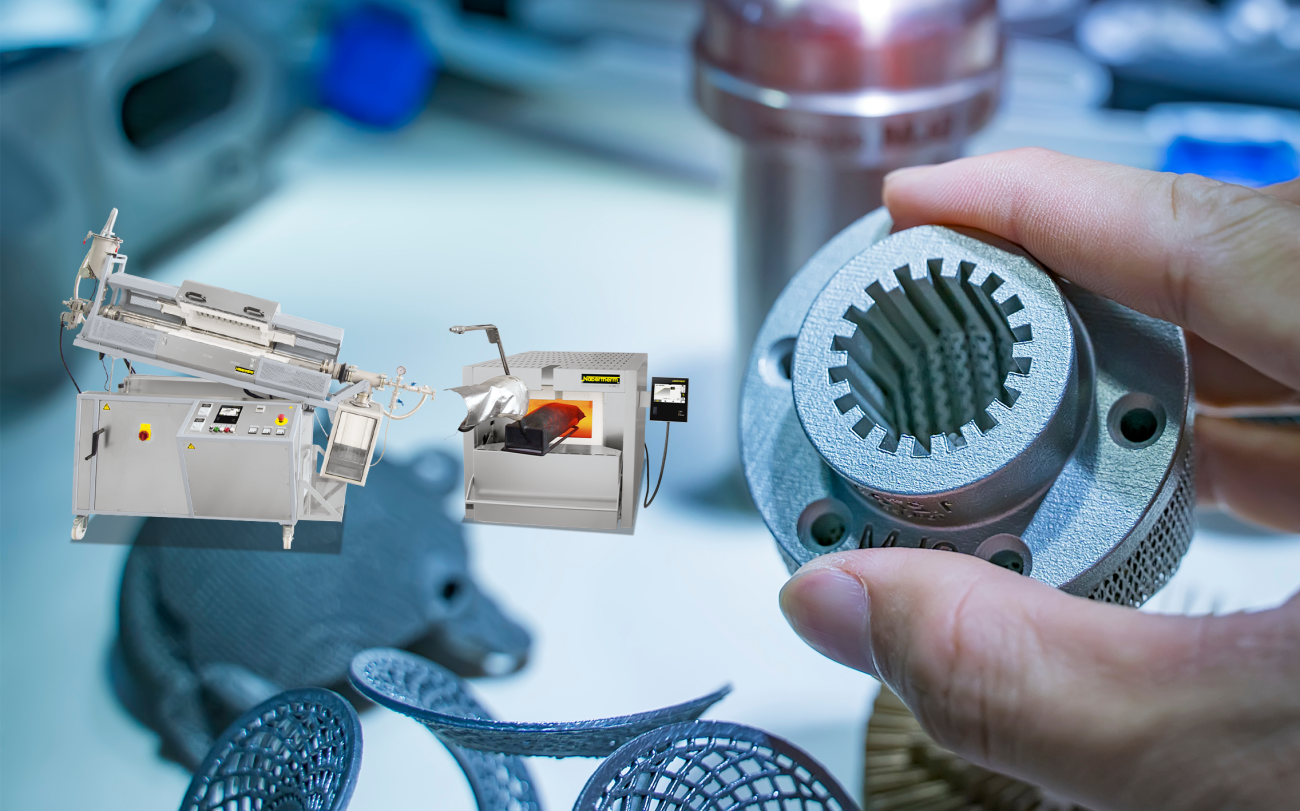

Salt-bath furnaces have an excellent temperature uniformity and ensure very good heat transfer to the work piece. Generally, heat treatment can be carried out with shorter dwell times than in chamber furnaces. Since the charge is heat treated with the exclusion of oxygen, scale and discoloration on the surface of the parts are kept to a minimum. The salt-bath furnaces TS 20/15 - TSB 90/80 can be used for heat treatment of metals in neutral and active salt baths. They are used for processes such as nitriding according to Tenifer up to 600 °C, carburization to 950 °C or bright annealing to 1000 °C.

The crucible is inserted so that it is suspended in the salt-bath furnace and can be replaced easily if necessary. Two crucible types are available:

- Type P: low carbon steel and CrNi plated for carburizing, neutral salt and annealing baths up to 850 °C

- Type C: high alloy CrNi steel for neutral salt and annealing baths up to 1000 °C

Crucibles are wearing parts because they are exposed to thermal stress during the heating and cooling process and corrosive salt. The following parameters influence wear of the crucible:

- Working temperature

- Number of heating and cooling cycles

- Salt

- Charge material

- Charge quantity

- Contamination of the charge

- The crucible must be checked regularly for wear and damage. We recommend to order a replacement crucible together with the furnace.

Salt-bath furnaces are available for heat treatment of steel and aluminum: Features for heat treatment of steel:

- Tmax in salt: 750 °C or 1000 °C

- Safety technology according to EN 60519-2

- Melt-bath control: the temperature is measured in the salt as well as inside the furnace behind the crucible

- Removable collar plate made of steel

- Insulated swing-away lid

- Temperature uniformity up to +/- 2 °C according to DIN 17052-1 in the salt bath

- Over-temperature limiter in the furnace chamber to protect persons and the furnace

- Crucible can be easily replaced

- Defined application within the constraints of the operating instructions

Features for heat treatment of aluminum like steel, but

- Tmax in salt: 550 °C

- Over-temperature limiter in the furnace chamber and in the salt bath to protect persons and the furnace

- Optical and acoustic alarm to warn if the critical temperature is exceeded

- Eurotherm 6100e temperature recorder to document the temperature profile

Salt-bath furnaces can be delivered electrically heated or gas-fired

- Electrically heated (TS models):

- Freely radiating, high quality heating elements on ceramic support tubes

- Crucible heated from four sides

- If a heating element is defective, the furnace can be heated with the remaining heating elements

- Gas-fired (TSB models):

- Burner system with optimized flame management: high level of efficiency with overpressure operation to prevent false air entering

- Burner technology according to DIN EN 7462, part 2

- Lateral exhaust gas feed around the crucible

Dodatkowe wyposażenie

Accessories

- Exhaust gas collection at crucible rim

- For the direct extraction of vapors and exhaust gases

- Flange on the back to connect the customer’s exhaust gas system

- Only in combination with a lid that is manually placed on top

- Pneumatic lid opening

- Pneumatic lateral movement of the swivel lid

- Manual lowering and raising of the lid with a lever

- Foot pedal control

- Not available in combination with exhaust gas collection at crucible rim

- Charging basket for bulk materials

- Possible lid closing over the salt bath with inserted charging basket

- For manual charging of small martempering and salt baths

- Charging with a crane or charging aid for large martempering and salt baths

- Process control and documentation via Nabertherm Control Center NCC for monitoring, documentation, and control

Specyfikacja techniczna

| Model | Tmax | Inner dimensions salt-bath crucible | Volume | Outer dimensions in mm | Heating | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|

| °C 2 | Ø in mm | h in mm | in l | W | D | H | power in kW 1 | connection | in kg | |

| TS 20/15 | 750 3 | 230 | 500 | 20 | 850 | 850 | 800 | 16 | 3-phase | 650 |

| TS 30/18 | 750 3 | 300 | 500 | 30 | 950 | 950 | 800 | 20 | 3-phase | 700 |

| TS 40/30 | 750 3 | 400 | 500 | 60 | 1050 | 1050 | 800 | 33 | 3-phase | 750 |

| TS 50/48 | 750 3 | 500 | 600 | 110 | 1150 | 1150 | 970 | 58 | 3-phase | 1000 |

| TS 60/63 | 750 3 | 610 | 800 | 220 | 1250 | 1250 | 970 | 70 | 3-phase | 1200 |

| TS 70/72 | 750 3 | 700 | 1000 | 370 | 1350 | 1350 | 1370 | 80 | 3-phase | 1500 |

| TS 90/80 | 750 3 | 900 | 1000 | 500 | 1600 | 1600 | 1400 | 100 | 3-phase | 1700 |

| TS, TSB 20/20 | 1000 | 230 | 500 | 20 | 850 | 850 | 800 | 21 | 3-phase | 650 |

| TS, TSB 30/30 | 1000 | 300 | 500 | 30 | 950 | 950 | 800 | 33 | 3-phase | 700 |

| TS, TSB 40/40 | 1000 | 400 | 500 | 60 | 1050 | 1050 | 800 | 44 | 3-phase | 750 |

| TS, TSB 50/60 | 1000 | 500 | 600 | 110 | 1150 | 1150 | 970 | 66 | 3-phase | 1000 |

| TS, TSB 60/72 | 1000 | 610 | 800 | 220 | 1250 | 1250 | 970 | 80 | 3-phase | 1200 |

| TS, TSB 70/90 | 1000 | 700 | 1000 | 370 | 1350 | 1350 | 1370 | 100 | 3-phase | 1500 |

| TS, TSB 90/80 | 1000 | 900 | 1000 | 500 | 1600 | 1600 | 1400 | 120 | 3-phase | 1700 |

| 1Depending on furnace design connected load might be higher 2Salt bath temperature 3Tmax for heat treatment of aluminum 550 °C |

||||||||||

| Process Examples with Petrofer and Durferrit Salts | |

|---|---|

| TS models up to 750 °C | |

| Nitriding | Nitrogen 420, Nitrogen 460, Nitrogen 500 |

| Annealing and blackening | SFS 240 |

| Hardening, Tempering, Annealing, Quenching | GS 185, GS 230, GS 250, GS 345, GS 405, GS 406, GS 430, GS 520 |

| Preheating, annealing of gold, silver or brass | GS 560, HS 545 |

| TS models up to 1000 °C | |

| Carbonitriding, carburizing | Carbogen VC, Carbogen OK |

| Annealing, hardening, preheating | HS 535, HS 545, HS 535, GS 560, GS 660 |

| Carburizing | Carbogen Universal, Carborapid + GS-ZS, Carbomax +GS-ZS, Carbogen 800/800 ST, Carbogen 1000/ 1000 ST, CECONTROL 50H, CECONTROL 80B, CECONTROL 110B, CECONSTANT 80, CECONSTANT 100 |

| Preheating of high-speed steel, annealing | GS 540, GS 660, GS 670, GS 750, HS 550, HS 635, HS 760 |

| Preheating, annealing of gold, silver or brass | GS 560, HS 545 |

| TS models for aluminum | |

| Artificial ageing, solution annealing | AS 135, AS 200, AS 225, AVS 220, AVS 250 |

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców i akcesoriów przeznaczonych do różnych procesów prowadzonych w atmosferze gazów reakcyjnych palnych i niepalnych, w kąpieli solnej lub w próżni można znaleźć w naszym katalogu „Technologia procesów termicznych II”.