Funkcja i wyposażenie

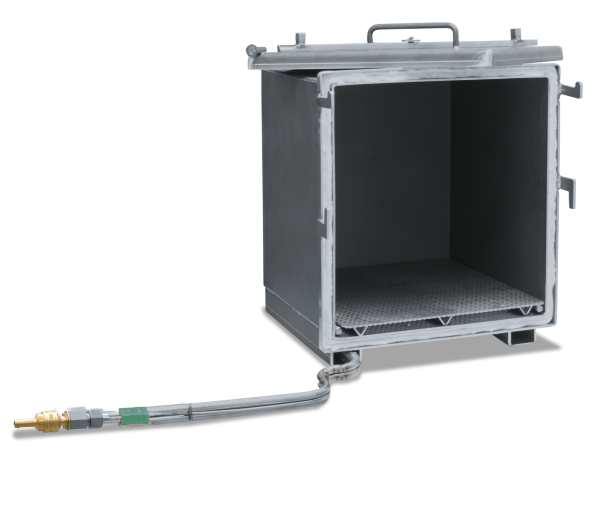

Protective Gases

Protective gases are used to force oxygen out of the gas feed boxes mentioned above. Make sure to use protective gases behaving neutrally toward the heat treated part. The protective gases should be inert, meaning no chemical bonding should occur with the workpiece or the furnace and no reactions should be enduced. In many cases, nitrogen is used as protective gas (lighter than air). Our experience shows that nitrogen does not always lead to sufficient results. A longer preflush time must also be used. Better results are achieved by adding a mixture of nitrogen and adding some hydrogen. Hydrogen acts as a reducing constituent and reacts with the oxygen. This gas mixture is known as forming gas and available in stores. Experience has shown that adding 5 % hydrogen to the nitrogen leads to good results. According to the EU material safety data sheet this mixture is considered as not flammable. National regulations, however, must be observed. This gas can be obtained in premixed form. No measures must be taken in advance to prevent explosions. If the workpiece has an affinity to hydrogen, argon used as protective gas can lead to good results. Argon is a gas which is heavier than air. This makes it relatively easy to fill the protective gas containers. Forming gas with added hydrogen (depending on the country law up to a ration of 98/2) is lighter, but it has the advantage of burning at higher temperatures and therefore binds with the oxygen. Even in a cold state, the leaking hydrogen transports the oxygen very easily out of the container. For gas mixtures with hydrogen or other combustible gases, the valid safety regulations must always be observed. If the mixture is declared as combustible, the furnace, provided it is a gas tight version, can be fitted with a corresponding safety system. Always make sure that the room is properly ventilated when working with protective gases. Country-specific safety regulations must also be followed.

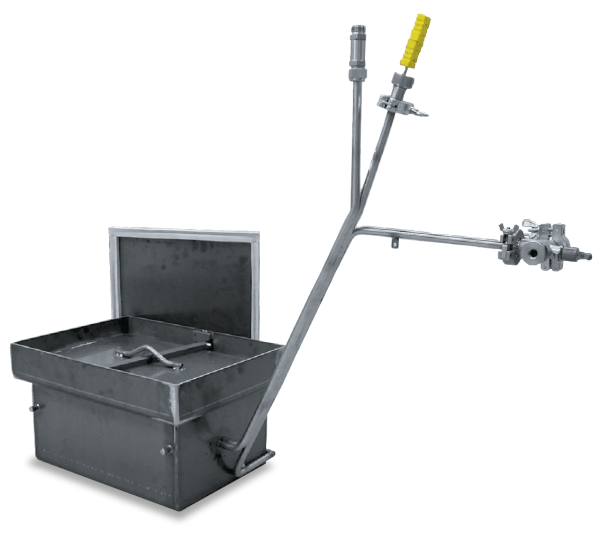

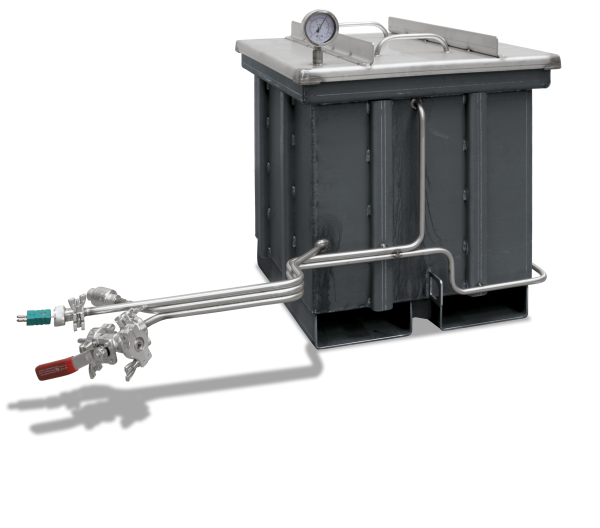

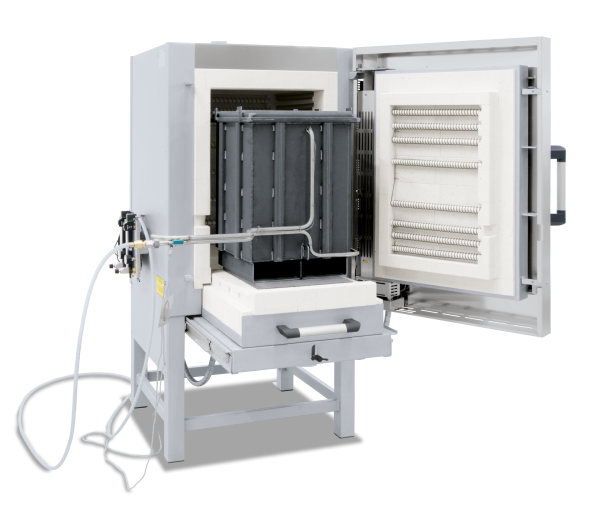

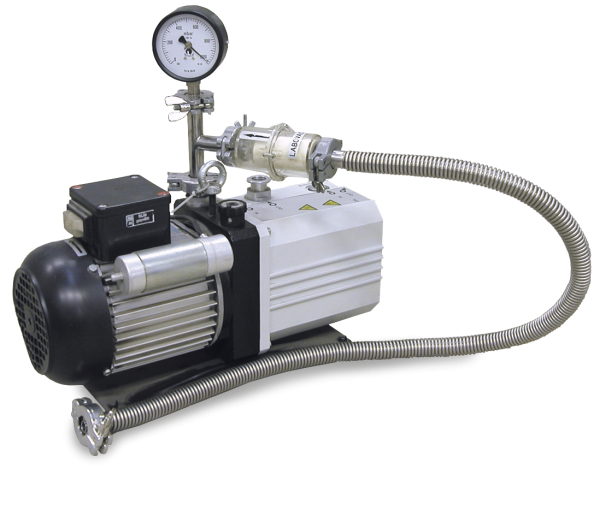

Automatic gas supply system for flow rates of 4 l - 50 l/min

- Gas supply system mounted at the furnace in a compact stainless steel housing

Gas flow can be activated in each segment by solenoid valve via the controller; Flow rate preset manually

Gas inlet: 1 bar - 10 bar, hose connection: Øi = 9 mm

Gas outlet: hose connection: Øi = 9 mm

System includes:

Solenoid valve with connection to the controller

Flow meter (scale as sticker)

Flow rate adjustment manually by screw and needle valve

Pressure reducer for setting the supply pressure

Pressure gauge for reading the supply pressure

Connection set for furnace

5 m connection hose 9 mm

Quick fitting (G1/4) for gas inlet

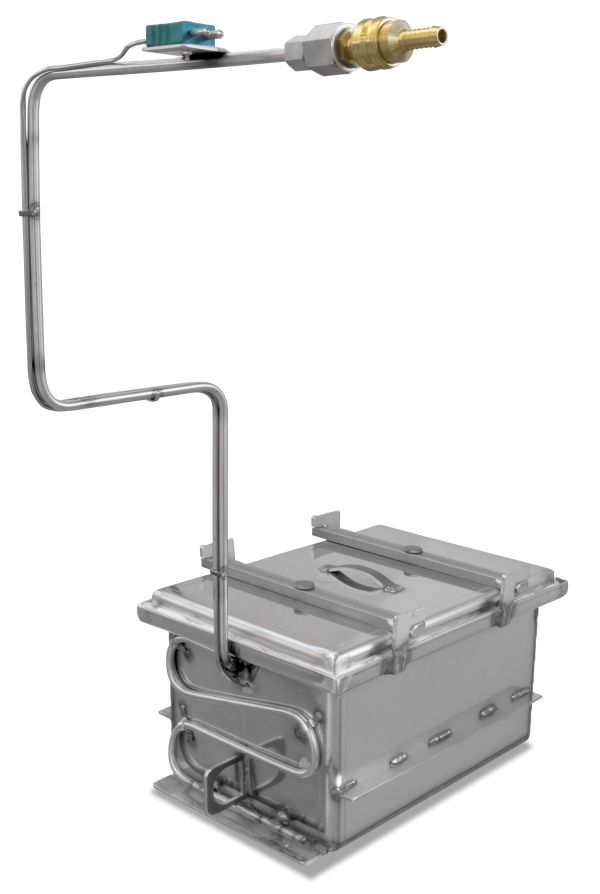

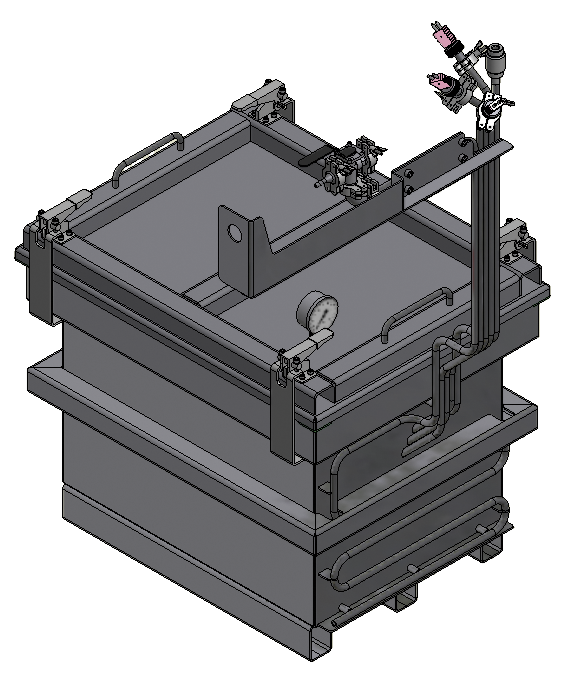

Automatic gas supply system for two flow rates 2 x 4 l - 50 l/min

- Gas supply systems mounted at the furnace in compact stainless steel housings

- Two combined gas supply systems depending on the connection for 2 gas quantities, 2 gas types or large gas quantity

- The gas supply can be activated in each segment by 2 solenoid valves, which can be selected independently via the controller. Gas flow rates pre-set manually

- Gas inlet: 1 bar - 10 bar, hose connection Øi = 9 mm

- Gas outlet: hose connection Øi = 9 mm

- System includes 2 combined systems, each with:

- Solenoid valve with connection to the controller

- Flow meter (scale as sticker)

- Flow rate adjustment manually by screw and needle valve

- Pressure reducer for setting the supply pressure

- Pressure gauge for reading the supply pressure

- Connection set for furnace

- 5 m connection hose 9 mm

- Quick fitting (G1/4) for gas inlet

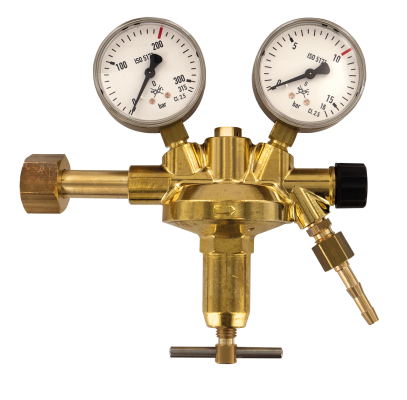

Gas bottle connection

- With this option, the gas supply systems can be connected to common gas bottles

- Bottle connection with:

- Pressure reducer

- Pressure gauge for inlet pressure

- Pressure gauge for outlet pressure

Specyfikacja techniczna

Automatic gas supply system for flow rates of 4 l - 50 l/min:

| Article no. | Type of gas | Flow rate |

|---|---|---|

| l/min | ||

| 6000085544 | gas independent | 4 - 50 |

Automatic gas supply system for two flow rates 2 x 4 l - 50 l/min:

| Article no. | Type of gas | Flow rate |

|---|---|---|

| l/min | ||

| 6000085545 | gas independent | 2 x 4 - 50 or 4 - 100 |

Gas bottle connection:

| Article no. | Type of gas | Gas- cylinder thread |

|---|---|---|

| 6000085489 | Argon | W21,8x1/14" (EU) |

| 6000085490 | Nitrogen | W24.32x1/14"RH (EU) |

| 6000085491 | Forming gas (95/5 and 98/2) | W21,8x1/14"LH(EU) |

| 6000085492 | Argon | W21.8x1/14"R (ES, FR, PT) |

| 6000085493 | Nitrogen | W21.8x1/14"R (ES, FR, PT) |

| 6000085494 | Forming gas (95/5 and 98/2) | W21.8L (ES, FR, PT) |

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców do obróbki cieplnej materiałów wytwarzanych metodą 3D można znaleźć w naszym katalogu „Produkcja addytywna”.