Funkcja i wyposażenie

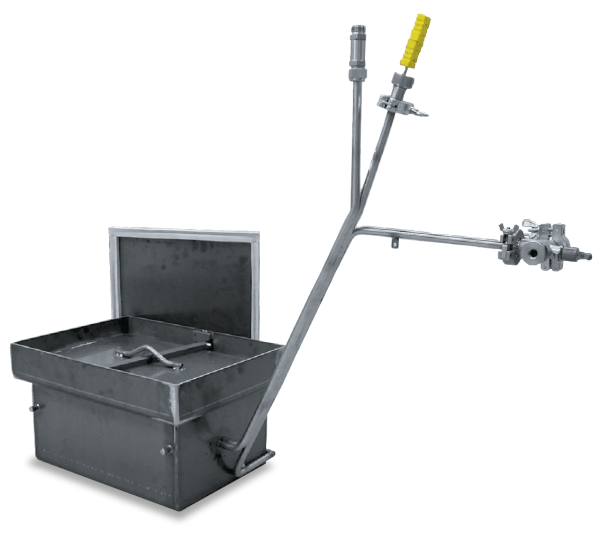

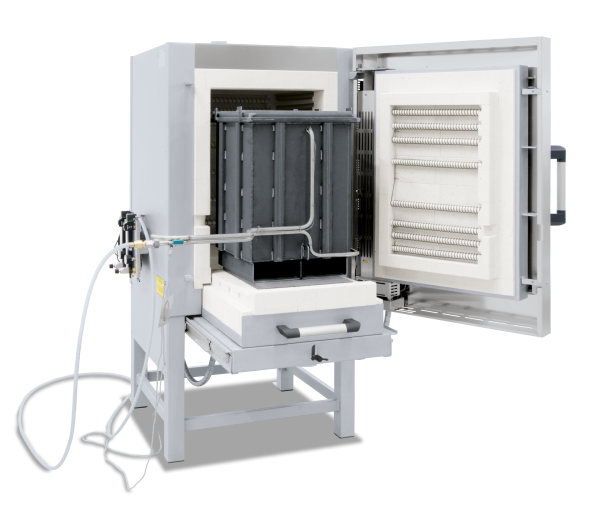

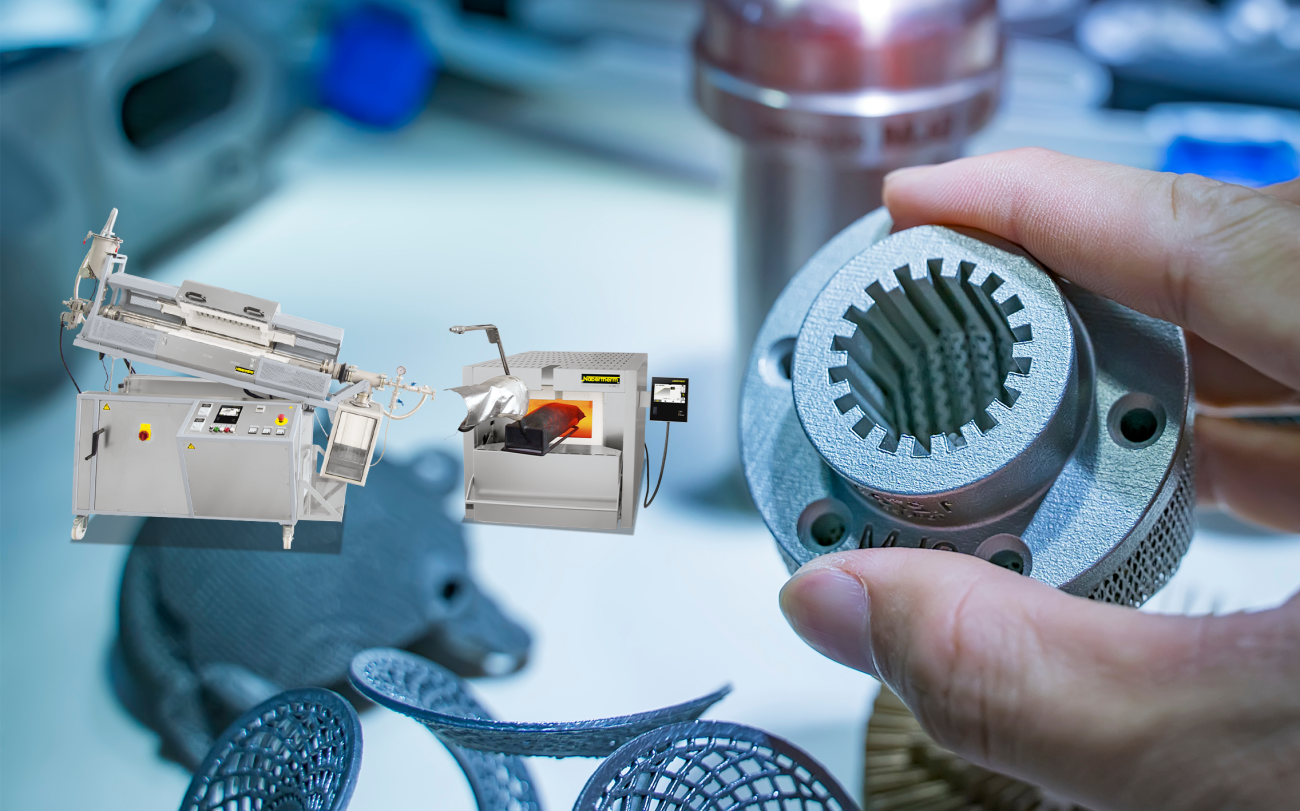

Protective gas box for furnaces with hinged door

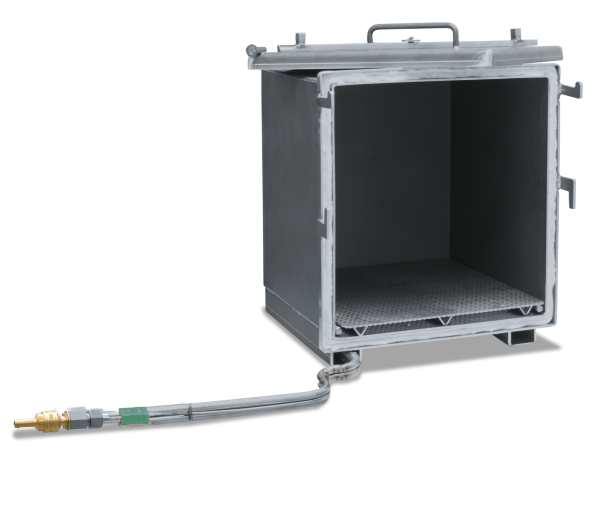

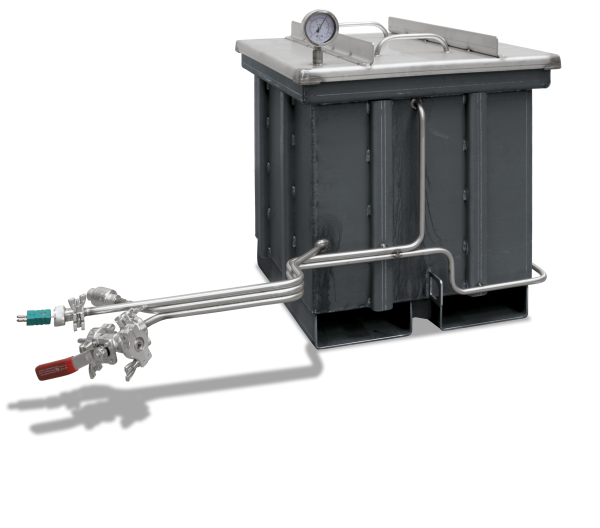

Due to the cubic interior of the LH chamber furnaces and the corresponding protective gas boxes, these furnaces are ideally suited for higher batches. Gassing boxes for the LH models have a standard charge thermocuple, which can be used, for example, for charge control. The protective gas inlet and outlet is routed through the furnace collar in the case of a furnace with a swivel door on the left and through the lower furnace collar in the lift-door configuration.

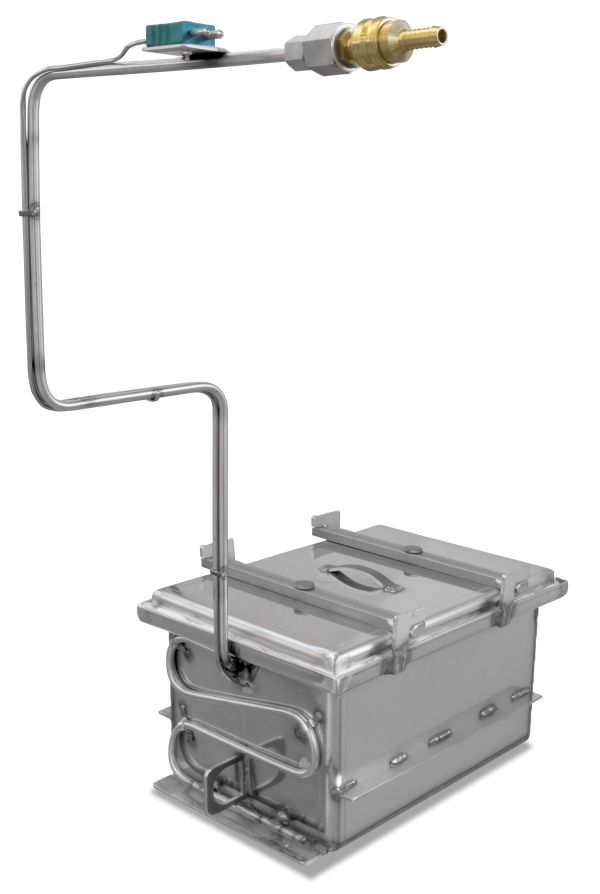

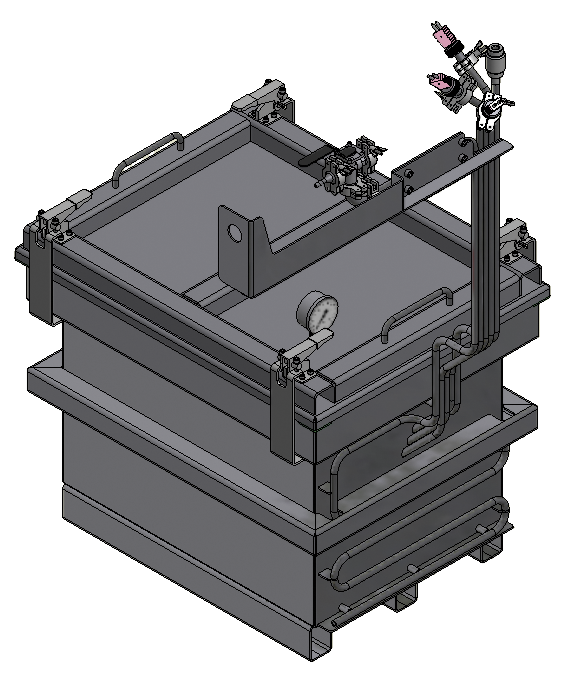

These boxes have a lid for charging from above, protective gas inlet and outlet.

- Tmax 1100 °C

- For non-combustible protective and reactive gases argon, nitrogen and forming gas (observe national regulations)

- Protective gas box with fiber seal and cover with locks, inert gas introduction via a pipe into the bottom of the box

- Protective gas connection via quick coupling with hose connector (inner diameter 9 mm)

- Piping for gas inlet and outlet through the furnace collar

- Heat-resistant alloy 314 (AISI)/(DIN material no. 1.4841)

- Charge thermocouple type K for temperature display or charge control

Dodatkowe wyposażenie

Additional equipment

- Starting from LH 30/.. a charging cart is recommended

- Digital temperature display

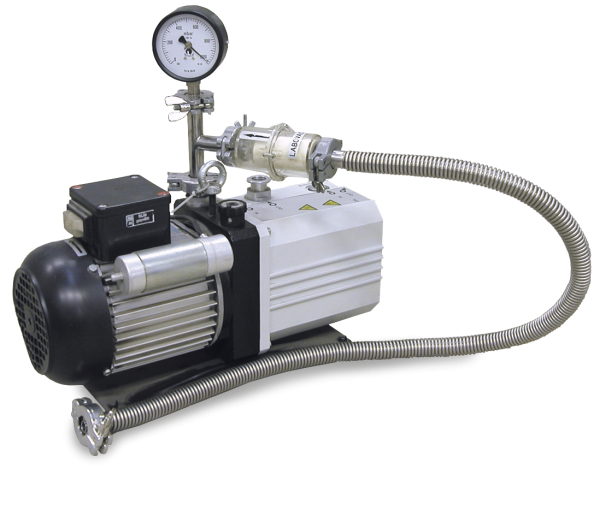

- Gas supply systems

- Extended gas piping for the use of smaller boxes in larger furnace models

- Draw hook

- Charging stacker

Specyfikacja techniczna

| Article no. | Furnace | Inner dimensions in mm | Outer dimensions in mm1 | Charging method | ||||

|---|---|---|---|---|---|---|---|---|

| w | d | h | W | D | H | of the box | ||

| 631001276 | LH 15/.. | 100 | 100 | 100 | 165 | 182 | 166 | draw hook |

| 631001277 | LH 30/.. | 170 | 170 | 170 | 235 | 252 | 236 | draw hook |

| 631001278 | LH 60/.. | 250 | 250 | 250 | 315 | 332 | 316 | draw hook |

| 631001279 | LH 120/.. | 350 | 350 | 350 | 415 | 411 | 441 | draw hook |

| 631001280 | LH 216/.. | 450 | 450 | 400 | 514 | 535 | 554 | charging stacker |

| Article no. 601655055, 1 set of fiber insulation cord, 5 strips of 610 mm each1 Without piping Work space = box inner dimensions: - 30 mm to all sides Larger boxes and custom dimensions available upon request |

||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców do obróbki cieplnej materiałów wytwarzanych metodą 3D można znaleźć w naszym katalogu „Produkcja addytywna”.